- Compact and cost-effective.

- Modular design to meet process requirements.

- Stem guided (up to DN 50) and post guided (from DN 65 to DN 100).

- Parabolic plug design.

- Stainless steel trim.

2 way

Two-way globe control valves V16/2 (EN)

The ADCATrol V16/2 is a series of single seated, two-way globe control valves designed for simple process engineering and industrial applications with non-critical operating conditions.

These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

- Bonnet extension for high and low temperatures.

- Various stem sealing options including bellows sealing.

- Soft or stellited valve sealing.

- Reduced bore trims.

- Silencers.

- Saturated and superheated steam.

- Hot and superheated water.

- Air, gases and others.

- V16/2G – SG iron.

- V16/2S – carbon steel.

- V16/2i – stainless steel.

- DN 15 to DN 100.

- V16/2G – Flanged EN 1092-2 PN 16.

- V16/2S and V16/2i – Flanged EN 1092-1 PN 16 or PN 40.

- Standard PN 16 DN 65 flanges are supplied with 4 holes. 8 holes, according to EN 1092-1/-2, on request.

Two-way globe control valves V16/2 (ASME)

The ADCATrol V16/2 is a series of single seated, two-way globe control valves designed for simple process engineering and industrial applications with non-critical operating conditions.

These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

- Compact and cost-effective.

- Modular design to meet process requirements.

- Stem guided (up to 2") and post guided (from 21/2" to 4").

- Parabolic plug design.

- Stainless steel trim.

- Bonnet extension for high and low temperatures.

- Various stem sealing options including bellows sealing.

- Soft or stellited valve sealing.

- Reduced bore trims.

- Silencers

- Saturated and superheated steam.

- Hot and superheated water.

- Air, gases and others.

- V16/2S – carbon steel

- 1/2" to 4"

- Flanged ASME B16.5 Class 150 or 300.

Two-way globe control valves V16/2 (THREADED)

The ADCATrol V16/2 is a series of single seated, two-way globe control valves designed for simple process engineering and industrial applications with non-critical operating conditions.

These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

- Compact and cost-effective.

- Modular design to meet process requirements.

- Parabolic plug design.

- Stainless steel trim.

- Bonnet extension for high and low temperatures.

- Various stem sealing options including bellows sealing.

- Soft or stellited valve sealing.

- Reduced bore trims including microflow.

- Saturated and superheated steam.

- Hot and superheated water.

- Air, gases and others.

- V16/2S – carbon steel.

- V16/2i – stainless steel.

- 1/2" to 2".

- Female threaded ISO 7 Rp or NPT.

Two-way globe control valves V25/2 (EN)

The ADCATrol V25/2 is a series of single seated, two-way globe valves designed for process engineering and industrial applications, where events such as erosion, cavitation or flashing may occur.

These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

- Robust construction.

- Modular design to meet process requirements.

- Stainless steel trim.

- Bonnet extension for high and low temperatures.

- Various stem sealing options including bellows sealing.

- Soft, stellited and high-performance metal valve sealing.

- V-port guided and perforated plugs.

- Low noise, anti-cavitation single and multi-stage trims.

- Reduced bore trims including microflow.

- Pressure balancing trims.

- Silencers.

- Saturated and superheated steam.

- Hot and superheated water.

- Air, gases and others

- V25/2G – SG iron.

- V25/2S – carbon steel.

- V25/2i – stainless steel (only available from DN 15 to DN 100).

- DN 15 to DN 200.

- V25/2G – Flanged EN 1092-2 PN 16.

- V25/2S and V25/2i – Flanged EN 1092-1 PN 16 or PN 40.

- Standard PN 16 DN 65 flanges are supplied with 4 holes. 8 holes, according to EN 1092-1/-2, on request.

Two-way globe control valves V25/2 (ASME)

The ADCATrol V25/2 is a series of single seated, two-way globe valves designed for process engineering and industrial applications, where events such as erosion, cavitation or flashing may occur.

These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

- Robust construction.

- Modular design to meet process requirements.

- Stainless steel trim.

- Bonnet extension for high and low temperatures.

- Various stem sealing options including bellows sealing.

- Soft, stellited and high-performance metal valve sealing.

- V-port guided and perforated plugs.

- Low noise, anti-cavitation single and multi-stage trims.

- Reduced bore trims including microflow.

- Pressure balancing trims.

- Silencers.

- Saturated and superheated steam.

- Hot and superheated water.

- Air, gases and others.

- V25/2S – carbon steel.

- 1/2" to 6".

- Flanged ASME B16.5 Class 150 or 300.

Pneumatic control valves PV40 (V40 globe valves series with linear actuators PA or EL series)

The PV40 control valves are single seated, two-way body constructed with in-line straight connections. The PA pneumatic actuator is rubber diaphragm and multi-springs. Its action can be DA – direct action (air to close) or RA – reverse action (air to open). The PV40 valves have been designed to ensure an accurate control in any process condition. Their wide application ranges allow the use of this valve with the most common process fluids such as water, superheated water, steam, air, gas and other non corrosive fluids.

PNEUMATIC ACTUATORS: PA205, PA280, PA340, PA435.

ACTUATOR CONN: 1/4” NPT-F.

CONTROL SIGNAL: 0,2 – 1bar; 0,4 – 1,2 bar; 0,4 – 2 bar.

ELECTRIC ACT.: Consult catalogue IS EL20.00 E.

HOW TO SELECT

Never size the valve according to the pipe diameter in which it has to be fitted, but according to the required actual flow of steam or water. Refer to valve calculation data sheet or consult the factory

- Single seated, two way, direct or reverse action valve.

- Valve top flange permanently attached to the body,

- removal is unnecessary for replacing the actuator.

- Metal to metal sealing as standard.

- Soft sealing.

- Position transmitter.

- Pneumatic pilot positioner.

- Air filter regulator.

- Top-work manual handwheel

- Saturated and superheated steam.

- Hot and superheated water.

- Diathermic oil.

- Air, gases and other no corrosive fluids

- PV40S-EV40S – steel construction.

- PV40I-EV40I – stainless steel.

- DN 15 to DN 50.

- Flanged EN 1092-1 or ANSI.

- Threaded connections on request.

3 way

Three-way globe control valves V303

The ADCATrol V303 is a series of single seated, three-way globe control valves designed to ensure accurate control in mixing and diverting process engineering and industrial applications.

These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

- Robust construction.

- Modular design to meet process requirements.

- Mixing and diverting versions.

- V-port guided plugs.

- Stainless steel trim.

- Bonnet extension for high and low temperatures.

- Various stem sealing options including bellows sealing.

- Saturated and superheated steam.

- Hot and superheated water.

- Thermal oil.

- Air, gases and others.

- V303S – carbon steel.

- V303i – stainless steel.

- DN 15 to DN 100.

- Flanged EN 1092-1 PN 16 or PN 40.

- Standard PN 16 DN 65 flanges are supplied with 4 holes. 8 holes, according to EN 1092-1/-2, on request.

Three-way globe control valves V253

The ADCATrol V253 is a series of three-way globe control valves designed to ensure accurate control in mixing or diverting general service applications.

These valves can be assembled with pneumatic, hydraulic or electric actuators and used with the most common process fluids such as water, superheated water, thermal oil, steam, air, gas and other non corrosive fluids.

- Compact and cost-effective design.

- Mixing and diverting versions.

- Various stem sealing options including bellows sealed versions

- Hot and superheated water.

- Thermal oil.

- Saturated and superheated steam.

- Air, gases and others.

- V253G – SG iron.

- DN 15 to DN 150

- PTFE/GR V-Rings – up to 220 ºC.

- Graphite packing – up to 350 ºC.

- Stainless steel bellows – up to 350 ºC.

- Flanged EN 1092-2 PN 16 or PN 25.

- Standard PN 16 DN 65 flanges are supplied with 4 holes. 8 holes, according to EN 1092-2, on request.

Pneumatic control valves V403 (V403 globe valves series with linear actuators PA or EL series)

The PV403 control valves are three-way valve body for mixing service. The PA pneumatic actuator is rubber diaphragm and multi-springs. Its action can be DA – direct action (air to close) or RA – reverse action (air to open). The V403 valves have been designed to assure an accurate control in any process condition. Their wide application ranges allow the use of this valve with the most common process fluids such as water, superheated water, diathermic oil, steam, air, gas and other non corrosive fluids.

PNEUMATIC ACTUATORS: PA205, PA280, PA340, PA435.

ACTUATORS CONNECTION: 1/4" NPT-F.

CONTROL SIGNAL: 0,2 – 1bar; 0,4 – 1,2 bar; 0,4 – 2 bar.

ELECTRIC ACT: Consult catalogue IS EL 20.00 E - Linear electric actuators.

MAX. AIR SUPPLY: 3,5 bar.

AMBIENT TEMP.: -20 ºC to 70 ºC.

BONNET: Standard – up to 220 ºC; Extended finned – above 220 ºC.

STEM SEALING:

PTFE/GR V-Rings – up to 220 ºC;

Graphite – up to 300 ºC;

Stainless steel bellows.

PLUG TYPES: Linear (PL).

PORT: Full port.

HOW TO SELECT: Never size the valve according to the pipe diameter in which it has to be fitted, but according to the required actual flow of steam or water. Refer to the valve calculation data sheet or consult the factory.

- Mixing or diverting control valve.

- Standard packing or bellows sealed stem sealing

- Soft sealing.

- Position transmitter.

- Pneumatic pilot positioner.

- Air filter regulator.

- Top-work manual handwheel.

- Hot and superheated water.

- Diathermic oil.

- Saturated and superheated steam.

- Air, gases and other non-corrosive fluids.

- PV403S-EV403S – steel construction.

- PV403I-EV403I – stainless steel.

- DN 15 to DN 50.

- Flanged EN 1092-1 PN40 or ANSI Class 150 lb / 300 lb.

- Threaded connections on request

On-Off Straight and angle pattern

Pneumatic ON/OFF globe valves PV15 (EN) DN15-200

The ADCATrol PV15 is a series of single seated, two-way pneumatic on/off globe valves with diaphragm actuator. These valves are suitable for use with the most common process fluids such as steam, water, superheated water, air, neutral gases and oils.

- Easy to service.

- Compact and cost-effective.

- Class VI shut-off with PTFE/GR soft sealing up to 200 ºC.

- Stem guided (up to DN 50) and post guided (from DN 65 to DN 100).

- Compact actuators with rolling diaphragm.

- High spring thrusts and stroking speeds.

- Yoke and stem coupling with mounting according to NAMUR (DIN IEC 60534-6-1).

- Ambient temperature from -10 ºC to 80 ºC.

- Top mounted handwheel.

- Filter regulators, solenoid valves and limit switches.

- Saturated steam.

- Hot and superheated water.

- Air, gases and others

- PV15G – SG iron.

- PV15S – carbon steel.

- PV15i – stainless steel.

- DN 15 to DN 200.

- PV15G – Flanged EN 1092-2 PN 16.

- PV15S and PV15i – Flanged EN 1092-1 PN 16 or PN 40.

- Standard PN 16 DN 65 flanges are supplied with 4 holes. 8 holes, according to EN 1092-1/-2, on request.

Pneumatic ON/OFF globe valves PV15 (ASME) 1/2"-6"

The ADCATrol PV15 is a series of single seated, two-way pneumatic on/off globe valves with diaphragm actuator.

These valves are suitable for use with the most common process fluids such as steam, water, superheated water, air, neutral gases and oils.

- Easy to service.

- Compact and cost-effective.

- Class VI shut-off with PTFE/GR soft sealing up to 200 ºC.

- Stem guided (up to 2") and post guided (from 21/2" to 4").

- Compact actuators with rolling diaphragm.

- High spring thrusts and stroking speeds.

- Yoke and stem coupling with mounting according to NAMUR (DIN IEC 60534-6-1).

- Ambient temperature from -10 ºC to 80 ºC.

- Top mounted handwheel.

- Filter regulators, solenoid valves and limit switches.

- Saturated steam.

- Hot and superheated water.

- Air, gases and others.

- PV15S – carbon steel

- PV15I - stainles steel

- 1/2" to 6".

- Flanged ASME B16.5 Class 150 or 300.

Pneumatic ON/OFF globe valves PPV15 (EN)

The ADCATrol PPV15 is a series of single seated, two-way pneumatic on/off globe valves with piston actuator. These valves are suitable for use with the most common process fluids such as steam, water, superheated water, air, neutral gases and oils.

- Easy to service.

- Compact and cost-effective.

- Class VI shut-off with PTFE/GR soft sealing up to 200 ºC.

- Robust and compact piston actuator with 360º rotation.

- Ambient temperature from -10 ºC to 80 ºC.

- M26 x 1,5 threaded connection on actuator.

- Solenoid valves and limit switches.

- Saturated steam.

- Hot and superheated water.

- Air, gases and others.

- PPV15G – SG iron.

- PPV15S – carbon steel.

- PPV15i – stainless steel.

- DN 15 - DN50

- PPV15G – Flanged EN 1092-2 PN 16.

- PPV15S and PPV15i – Flanged EN 1092-1 PN 16 or PN 40.

Pneumatic on/off globe valves PPV15 (ASME)

The ADCATrol PPV15 is a series of single seated, two-way pneumatic on/off globe valves with piston actuator. These valves are suitable for use with the most common process fluids such as steam, water, superheated water, air, neutral gases and oils.

- Easy to service.

- Compact and cost-effective.

- Class VI shut-off with PTFE/GR soft sealing up to 200 ºC.

- Robust and compact piston actuator with 360º rotation.

- Ambient temperature from -10 ºC to 80 ºC.

- M26 x 1,5 threaded connection on actuator.

- Solenoid valves and limit switches.

- Saturated steam.

- Hot and superheated water.

- Air, gases and others.

- PPV15S – carbon steel.

- 1/2" to 2"

- Flanged ASME B16.5 Class 150 or 300.

Pneumatic on/off angle seat PAV21 (Threaded)

The ADCATrol PAV21 is a series of pneumatic angle seat shut-off valves with piston actuators. These valves are suitable for use with the most common process fluids such as steam, water, superheated water, air, neutral gases and oils. The PAV21 is recommended for applications where flexibility and affordability are important requirements.

- Corrosion resistant stainless steel body.

- Easy to service.

- Compact and cost-effective with high flow capacity.

- Self-centering plug with Class VI shut-off and PTFE/GR soft sealing up to 200 ºC.

- Robust and compact piston actuator with 360º rotation.

- Ambient temperature from -10 ºC to 80 ºC.

- M26 x 1,5 threaded connection on actuator.

- Solenoid valves and limit switches.

- Saturated steam.

- Hot and superheated water.

- Air, gases and others.

- PAV21.

- 1/2" to 2".

- Female threaded ISO 7 Rp or NPT.

Electric on/off globe valve DN15-200 EV15 (EN)

The ADCATrol EV15 is a series of two-way, single-seat electric on/off globe valves with an electric actuator. These valves are suitable for use with most common process fluids, such as steam, water, superheated water, air, neutral gases, and oils.

- Easy maintenance.

- Compact and cost-effective.

- Ambient temperature from -10 to 60 °C (others on request).

- Supply voltages: 24 V AC, 115 V AC, 230 V AC, 400 V AC 50/60 Hz and 24 V DC.

- Manual operation with motor decoupling from the actuator.

- Valve protection against excessive forces thanks to the load-dependent seat.

- Closing force defined at the end positions, resulting in a tight valve closure.

- Mechanical stroke indication via anti-rotation bar.

- Limit switches.

- Heating element.

- Saturated steam.

- Hot and superheated water.

- Air, gases, and others.

- EV15G – SG cast iron.

- EV15S – Carbon steel.

- EV15i – Stainless steel.

- DN 15 to DN 200.

- EV15G: EN 1092-2 PN 16 flange.

- EV15S and EV15i: EN 1092-1 PN 16 or PN 40 flange.

- Standard PN 16 DN 65 flanges are supplied with 4 holes. 8 holes, according to EN 1092-1/-2, on request

Electric on/off globe valve DN15-150 EV15 (ASME)

The ADCATrol EV15 is a series of two-way, single-seat electric globe valves with electric actuators. These valves are suitable for use with most common process fluids, such as steam, water, superheated water, air, neutral gases, and oils.

- Easy maintenance.

- Compact and cost-effective.

- Ambient temperature from -10 to 60 °C (others on request).

- Supply voltages: 24 VAC, 115 VAC, 230 VAC, 400 VAC 50/60 Hz, and 24 V DC

- Manual operation with motor decoupling from the actuator.

- Valve protection against excessive forces due to load-dependent seat.

- Closing force defined at the end positions, resulting in a tight valve closure.

- Mechanical stroke indication via anti-rotation bar.

- Limit switches.

- Heating element.

- Saturated steam.

- Hot and superheated water.

- Air, gases, and others

- EV15S: carbon steel.

- EV15i: stainless steel.

- ½“ to 6”.

- With ASME B16.5 Class 150 or 300 flange.

Pneumatic / Electric Actuators

Linear pneumatic actuators PA (100 cm² to 2400 cm²)

PA series pneumatic multi-spring actuators with rolling diaphragm, offering decreased hysterisis and good linearity throughout the operating range. Available in air to close and air to open versions, for modulating and on/off services.

- Multi-spring compact design.

- Actuators with rolling diaphragm.

- High spring thrusts and stroking speeds.

- Strokes up to 60 mm.

- Sizes from 100 cm² to 2400 cm².

- Yoke and stem coupling with mounting according to NAMUR (DIN IEC 60534-6-1).

- Operation temperature range from -20 ºC to 80 ºC.

- Top mounted handwheel.

- Stroke limiter.

- Stainless steel construction.

- Positioners, limit switches, I/P converters, volume boosters, feedback units and others.

- Actuation of ADCATrol control valves, or others on request.

- PA10, PA25, PA40, PA80, PA80D and PA80T – mild steel.

- PA10i, PA25i and PA40i – stainless steel.

Linear pneumatic actuators PA206, PA281, PA341 and PA436 (140 cm² to 700 cm²)

PA series pneumatic multi-spring actuators with rolling diaphragm, offering decreased hysterisis and good linearity throughout the operating range. Available in air to close and air to open versions, for modulating and on/off services.

- Multi-spring compact design.

- Actuators with rolling diaphragm.

- High spring thrusts and stroking speeds.

- Strokes up to 30 mm.

- Sizes from 140 cm² to 700 cm².

- Yoke and stem coupling with mounting according to NAMUR (DIN IEC 60534-6-1).

- Operation temperature range from -20 ºC to 80 ºC.

- Top mounted handwheel.

- Stroke limiter.

- Stainless steel construction.

- Positioners, limit switches, I/P converters, volume boosters, feedback units and others.

- Actuation of ADCATrol control valves, or others on request.

- PA206, PA281, PA341 and PA436 – mild steel.

- PA206i, PA281i, PA341i and PA436i – stainless steel.

- For other models, please consult IS PV3.70 – PA linear pneumatic actuators.

Manual operated linear actuators MAH

The ADCATrol MAH is a series of manual linear actuators with top mounted handwheel designed for use with modulating and shut off valves. These actuators are particularly interesting for control applications where a precise manual adjustment of flow is required. These actuators can also be quickly assembled to control valves allowing processes to continue operation while the original actuator is being serviced or replaced.

- Compact and simple to install.

- Strokes up to 60 mm.

- Operating temperature range from -20 ºC to 100 ºC.

- Locking mechanism to lock the valve stem in place and prevent accidental or unauthorized operation.

- Stainless steel construction

- Actuation of ADCATrol control valves, or others on request.

- MAH180, MAH250 and MAH400.

Linear electric actuators EL (1,2 kN to 25 kN)

The EL series linear electric actuators are designed for operation of control valves in modulating and on/off services in process engineering and industrial applications. The self-locking stem nut is driven by an electric motor via a gearing.

Load-dependent switches and/or mechanical limit switches define the stops for the end positions.

- Modular retrofittable design.

- 24 V AC, 115 V AC, 230 V AC, 400 V AC 50/60 Hz and 24 V DC supply voltages.

- Manual operation with disengagement of the actuator motor.

- IP 65 (EL12 IP 43) protection.

- Valve protection against excessive force due to load-dependent seating.

- Mounting to valves made via yoke or mounting flange DIN 3358, enabling easy connection to all types of valves. Standard version is suitable for ADCATrol valves.

- Defined closing force in the end positions leading to tight valve shut-off.

- Stall proof synchronous motors (or brake motors for higher positioning forces) ensure highest positioning accuracy.

- Mechanical stroke indication via anti-rotation bar.

- Exact, backlash-free measurement of actual valve stroke by direct coupling to the valve stem.

- Universally usable actuators due to control via 3-point-step controllers, analogue input signals (0 to 10 V, 0(4) to 20 mA), or fieldbus systems.

- Limit switches are easily adjustable for stroke limitation or as signal for intermediate positions.

- Electronic positioner.

- Additional limit switches.

- Potentiometers e.g. for 3-point-step control in closed loop.

- 0(4) to 20 mA electronic position feedback units.

- Heating resistor.

- Special coatings and finishes for aggressive environments.

- Actuation of ADCATrol control valves, or others on request.

- EL12, EL20, EL45, EL80, EL120 and EL250.

Linear electric actuators with Fail-Safe Function ELR

The ELR series linear electric actuators are designed for operation of control valves in modulating and on/off services in process engineering and industrial applications. The self-locking stem nut is driven by an electric motor via a gearing.

Load-dependent switches and/or mechanical limit switches define the stops for the end positions.

In case of power failure, the electric linear actuator runs into the respective fail-safe position by spring force (thrust rod either extended or retracted).

In modulating duty, the end position seating is made via mechanical limit switches.

- Modular retrofittable design.

- 24 V AC, 115 V AC, 230 V AC, 400 V AC 50/60 Hz and 24 V DC supply voltages.

- Electric manual operation with OPEN/CLOSE buttons.

- IP 54 protection.

- Valve protection against excessive force due to load-dependent seating.

- Mounting to valves made via yoke or mounting flange DIN 3358, enabling easy connection to all types of valves. Standard version is suitable for ADCATrol valves.

- Defined closing force in the end positions leading to tight valve shut-off.

- Stall proof synchronous motors (or brake motors for higher positioning forces) ensure highest positioning accuracy.

- Mechanical stroke indication via anti-rotation bar.

- Exact, backlash-free measurement of actual valve stroke by direct coupling to the valve stem.

- Universally usable actuators due to control via 3-point-step controllers, analogue input signals (0 to 10 V, 0(4) to 20 mA), or fieldbus systems.

- Limit switches are easily adjustable for stroke limitation or as signal for intermediate positions.

- Electronic positioner.

- Additional limit switches.

- Potentiometers e.g. for 3-point-step control in closed loop.

- 0(4) to 20 mA electronic position feedback units.

- Heating resistor.

- Special coatings and finishes for aggressive environments.

- Actuation of ADCATrol control valves, or others on request.

- ELR2.1, ELR2.2 and ELR2.3.

Intelligent linear electric actuators ELS (2,3 kN to 25 kN)

The ADCATrol ELS series intelligent linear electric actuators are designed for operation of control valves in modulating and on/off services in process engineering and industrial applications. The actuator is equipment as standard with positioner and active feedback function, automatic commissioning as well as comprehensive diagnostic functions.

The ELS is optionally available with super capacitors for fail-safe operation, returning to its respective fail-safe position in case of power failure/interruption.

- Modular retrofittable design.

- Automatic comissioning with the press of one button.

- 115 V AC, 230 V AC 50/60 Hz and 24 V AC/DC supply voltages.

- Manual operation with handwheel.

- IP 65 protection (IP 67 on request).

- Mounting to valves made via yoke or mounting flange DIN 3358, enabling easy connection to all types of valves. Standard version is suitable for ADCATrol valves.

- Sturdy metal main frame for mainboard and accessories.

- Mechanical stroke indication via anti-rotation bar.

- Friction clutch for easy and tool-free adaptation to the valve stroke.

- Universally usable actuators due to control via 3-point-step controllers and analog input signals (0(2) to 10 V, 0(4) to 20 mA).

- Additional limit switches.

- Electric fail-safe with super capacitors.

- Local control to enable manual operation through the use of buttons and on site diagnosis without needing a PC.

- Profibus DP and Modbus RTU communication.

- Heating resistor.

- IP 67 metal cover.

- Silicone free version.

- Actuation of ADCATrol control valves, or others on request.

- ELS20, ELS20.1, ELS45, ELS45.1, ELS80, ELS100, ELS100.1, ELS140, ELS200 and ELS250.

Linear electric actuators AVF234S and AVM234S

The AVM234S / AVF234S valve actuators offer automatic adaptation to the stroke of the valve, precision activation and high energy efficiency with minimal operating noise.

Ideal for use with any DSH series direct steam injection humidifier and in TDS (Total Dissolved Solids) control systems VCP blowdown valves.

In case of power failure/interruption, the AVF234S actuator runs, spring driven, into its respective fail-safe position (thrust rod extended). In modulating duty, the end position seating is made via limit switches.

- IP 66 protection.

- Automatic detection of control signal with LED indications.

- Adjustable characteristic curve (linear, quadratic and equal-percentage) and running time via DIP switch.

- Automatic adaptation to valve stroke.

- Manual operation with disengagement of the actuator motor.

- Mechanical stroke indication.

- Spring-return feature (AVF234S).

- Switching input (2-point or 3-point-step control) or analog input (0...10 V or 4...20 mA).

- Split-range unit for adjusting sequences.

- 230 V AC and 100 V AC power supply modules.

- Auxiliary change over contacts.

- Potentiometers, e.g. for 3-point-step in closed loop.

- Adapters for high temperature conditions.

- Actuation of V series ADCATrol control valves, or others on request.

- AVM234S.

- AVF234S - Fail-safe with spring-return.

Self-acting temperature control valves

Self-acting temperature regulators TR25S

The TR25 series of temperature regulators were designed for direct acting temperature control systems where the valve closes on temperature rise.

They are single seated, unbalanced and intended to be coupled with T series thermostat models T.205 and T.405.

The liquid filling the thermostat expands when the temperature of the fluid being heated rises, closing the valve.

These valves are used for controlling temperature in central and district heating systems, heat exchangers and other HVAC and industrial applications.

- Easily adjustable temperature range.

- Proportional temperature control.

- Single seated, two way, direct acting valve.

- Built-in strainer.

- Narrow thermostat neutral zone (1,5 to 2,5 ºC).

- No special tools required for servicing.

- Stuffing box is an integral part of the thermostatic element, allowing easy and simple maintenance of the valve.

- PK sensor pocket.

- K1 cooling unit.

- Diffferent capillary lenghts.

- Other thermostats on request.

- Saturated and superheated steam.

- Hot and superheated water.

TR25S – carbon steel.

AVAILABLE THERMOSTATS:

- T.205 – 400 N (max. closing force).

T.405 – 500 N (max. closing force).

- 1/2" to 1".

- Female threaded ISO 7 Rp.

- T.205: 0 – 60 ºC, 30 – 90 ºC and 60 – 120 ºC.

- T.405: 0 – 120 ºC and 40 – 160 ºC.

- Horizontal installation with the thermostat in the vertical position, in order to reduce wear.

In case of medium temperatures up to 150 ºC, the thermostat may be fitted below or above the valve. - In case of medium temperatures between 150 and 250 ºC, a cooling unit type K1 has to be applied with the connection pointing downwards.

- A “Y” strainer should be installed upstream of the valve.

- See IMI – Installation and maintenance instructions.

Self-acting temperature regulators TR40 DN15 DN25

The TR40 series of temperature regulators were designed for direct acting temperature control systems where the valve closes on temperature rise. They are single seated, unbalanced and intended to be coupled with T series thermostat models T.205 and T.405. The liquid filling the thermostat expands when the temperature of the fluid being heated rises, closing the valve.

These valves are used for controlling temperature in central and district heating systems, heat exchangers and other HVAC and industrial applications.

- Easily adjustable temperature range.

- Proportional temperature control.

- Single seated, two way, direct acting valve.

- Built-in strainer.

- Narrow thermostat neutral zone (1,5 to 2,5 ºC).

- No special tools required for servicing.

- Stuffing box is an integral part of the thermostatic element, allowing easy and simple maintenance of the valve.

- PK sensor pocket.

- K1 cooling unit.

- Diffferent capillary lenghts.

- Other thermostats on request.

- Saturated and superheated steam.

- Hot and superheated water

- TR40S – carbon steel.

- TR40SS – stainless steel.

AVAILABLE THERMOSTATS

- T.205 – 400 N (max. closing force).

- T.405 – 500 N (max. closing force).

- DN 15 to DN 25.

- Flanged EN 1092-1 PN 40.

- T.205: 0 – 60 ºC, 30 – 90 ºC and 60 – 120 ºC.

- T.405: 0 – 120 ºC and 40 – 160 ºC.

- Horizontal installation with the thermostat in the vertical position, in order to reduce wear.

- In case of medium temperatures up to 150 ºC, the thermostat may be fitted below or above the valve. In case of medium temperatures between 150 and 250 ºC, a cooling unit type K1 has to be applied with the connection pointing downwards.

- A “Y” strainer should be installed upstream of the valve. See IMI – Installation and maintenance instructions.

Self-acting temperature regulators TR25SS DN10 (1/4” Y 3/8”)

The TR25 series of temperature regulators were designed for direct acting temperature control systems where the valve closes on temperature rise. They are single seated, unbalanced and intended to be coupled with T series thermostat model T.205. The liquid filling the thermostat expands when the temperature of the fluid being heated rises, closing the valve.

These valves are used for controlling temperature in central and district heating systems, heat exchangers and other HVAC and industrial applications.

- Easily adjustable temperature range.

- Proportional temperature control.

- Single seated, two way, direct acting valve.

- Built-in strainer.

- Narrow thermostat neutral zone (1,5 to 2,5 ºC).

- No special tools required for servicing.

- Stuffing box is an integral part of the thermostatic element, allowing easy and simple maintenance of the valve.

- PK sensor pocket.

- K1 cooling unit.

- Diffferent capillary lenghts.

- Other thermostats on request.

- Saturated and superheated steam.

- Hot and superheated water.

- TR25SS – stainless steel.

AVAILABLE THERMOSTATS

- T.205 – 400 N (max. closing force).

- 1/4" and 3/8".

- Female threaded ISO 7 Rp.

- T.205: 0 – 60 ºC, 30 – 90 ºC and 60 – 120 ºC.

- Horizontal installation with the thermostat in the vertical position, in order to reduce wear.

- In case of medium temperatures up to 150 ºC, the thermostat may be fitted below or above the valve. In case of medium temperatures between 150 and 250 ºC, a cooling unit type K1 has to be applied with the connection pointing downwards.

- A “Y” strainer should be installed upstream of the valve. See IMI – Installation and maintenance instructions.

Self-acting temperature regulators TR25SS (1/2” to 1”)

The TR25 series of temperature regulators were designed for direct acting temperature control systems where the valve closes on temperature rise. They are single seated, unbalanced and intended to be coupled with T series thermostat model T.205. The liquid filling the thermostat expands when the temperature of the fluid being heated rises, closing the valve.

These valves are used for controlling temperature in central and district heating systems, heat exchangers and other HVAC and industrial applications.

- Easily adjustable temperature range.

- Proportional temperature control.

- Single seated, two way, direct acting valve.

- Built-in strainer.

- Narrow thermostat neutral zone (1,5 to 2,5 ºC).

- No special tools required for servicing.

- Stuffing box is an integral part of the thermostatic element, allowing easy and simple maintenance of the valve.

- PK sensor pocket.

- K1 cooling unit.

- Diffferent capillary lenghts.

- Other thermostats on request.

- Saturated and superheated steam.

- Hot and superheated water.

- TR25SS – stainless steel.

AVAILABLE THERMOSTATS: T.205 – 400 N (max. closing force).

- 1/4" and 3/8".

- Female threaded ISO 7 Rp.

- T.205: 0 – 60 ºC, 30 – 90 ºC and 60 – 120 ºC.

Self-acting temperature regulators TR25/R (Reverse action for cooling systems)

The TR25/R valves series are designed for temperature control in cooling systems where the valve opens with temperature rise. They are single seated, unbalanced and intended to be coupled with T series thermostat models T.205 and T.405. The liquid filling the thermostat expands when the temperature of the fluid being cooled rises, opening the valve.

- Easily adjustable temperature range.

- Proportional temperature control.

- Single seated, two way, reverse acting valve.

- Built-in strainer.

- Narrow thermostat neutral zone (1,5 to 2,5 ºC).

- No special tools required for servicing.

- Stuffing box is an integral part of the thermostatic element, allowing easy and simple maintenance of the valve.

- PK sensor pocket.

- Diffferent capillary lenghts.

- Other thermostats on request.

- Water, air ad other gases and liquids compatible with the construction.

- TR25S/R – carbon steel.

- TR25i/R – stainless steel.

AVAILABLE THERMOSTATS

- T.205 – 400 N (max. closing force).

- T.405 – 500 N (max. closing force).

- 1/2" to 1"; DN 15 to DN 25.

- Female threaded ISO 7 Rp.

- Flanged EN 1092-1 PN 40.

- T.205: 0 to 60 ºC, 30 to 90 ºC and 60 to 120 ºC.

- T.405: 0 to 120 ºC and 40 to 160 ºC.

- Horizontal installation with the thermostat in the vertical position, in order to reduce wear.

- A “Y” strainer should be installed upstream of the valve.

- See IMI – Installation and maintenance instructions.

Instruments and Accesories

Pressure transmitters PCS1

The ADCATrol PCS1 is a series of pressure transmitters suitable for all industrial applications. It is specially designed to operate in severe conditions where high temperatures, pressure peaks, shock and vibrations are present.

The PCS1 is extremely robust and reliable, thanks to its state of the art SMD electronics and compact all stainless steel construction.

- Compact stainless steel construction.

- Extended process media temperature from -40 ºC to 125 ºC.

- 2-wire 4 to 20 mA loop output.

- Available in multiple pressure ranges.

- Accuracy < 0.5% of full scale.

- Fast response (< 1 ms).

- Capable of withstanding high levels of mechanical shock and vibrations.

- Siphons and connector fitting adaptors for ADCA GS series siphons.

- M12 electrical connection with IP 67 rating.

- Pressure measurement in pipelines and vessels.

- PCS1.

- 1/4".

- Male threaded ISO 228 G.

- In any position.

- See IMI – Installation and maintenance instructions.

Temperature sensors TRPT1

The ADCATrol TRPT1 is a series of Pt100 resistance temperature sensors specially designed for general industrial use. The sensing element is an RTD three wire device according to EN 60751 Class A.

The sensor consists of a probe, a connection head and a measurement insert. The probe is made of austenitic stainless steel and the connection head is made of aluminium. The supply lines to the measurement insert are insulated from each other and from the probe tube with a ceramic insulator.

The sensor can be connected directly to a temperature indicator or controller that has a three wire Pt100 input.

- Head type B-KNE.

- Three wire sensing element.

- Fast response time.

- Easy to install.

- Transmitter assembly with 4 to 20 mA output.

- Sanitary version with clamped connection.

- Design for air temperature measurements.

- Special insertion lengths.

- ATEX approved version.

- Higher operating limits

- Temperature measurement in pipelines and vessels.

- TRPT1 – Pt100 sensor.

- TRPT1T – Pt100 sensor with analog transmitter.

- 1/2".

- Male threaded ISO 228 G.

- In any position.

- See IMI – Installation and maintenance instructions.

Direct solenoid valve SV32

3/2 way solenoid valves are available as single station units and they are designed for use with compressed air, mainly applied where on-off control is required with pneumatic actuators.

- Other versions under request.

- Pneumatic actuator control, among others.

- SV32C – direct acting.

- SV32H – pilot operated.

- 1/4”

- Female threaded ISO 7 Rp

- In any position.

- See IMI – Installation and maintenance instructions.

Universal display UD-720

The ADCATrol UD-720 is a programmable digital panel display used for the measurement of standard sensor and analog signals applied in automation. It is ideally suited for use with our range of instrumentation such as pressure transmitters, temperature probes and others. The unit features a 24 V DC supply output for transmitters.

- Easy to comission with user-friendly interface.

- Measuring inputs for resistance thermometer (RTD), thermocouples (TC), 0(4) to 20 mA, 0 to 10 V, 0 to 60 mV and resistance (Ω).

- 2 NO relay alarm outputs.

- 6 types of alarm functions.

- 24 V DC supply output to power transmitters and others.

- Three color display (14 mm high) with programmable color settings based on the measured value.

- 21-point individual characteristic function for input rescaling and conversion.

- Galvanically isolated inputs and outputs.

- Fully programmable from the front panel.

- Password protection.

- IP rating IP 65.

- Change-over relay alarm outputs.

- 0(4) to 20 mA and 0 to 10 V outputs for retransmission of any of the measured inputs.

- RS-485 Modbus RTU communication.

- UD-720.

Universal process controllers UC-820

The ADCATrol UC-820 is a digital universal controller used in the automation of industrial processes. It is ideally suited for use with our range of instrumentation, electric and pneumatic control valves and other electrical equipment.

The controller includes a set of universal type inputs for RTD, thermocouple (TC), logic (binary) and analog inputs. The controller has options for relay, open-collector (OC) and analog outputs using the innovative SMART PID algorithm.

- Universal measuring input: Resistance thermometer (RTD), thermocouples (TC), 0(4) to 20 mA and 0 to 5/10 V.

- Set point value: constant, programmed or from the additional analog input.

- On/off, PID, PID three-step and two-step control (valve control) or PID of heating-cooling type.

- 2 NO relay alarm outputs and 2 other outputs of choice between relay, OC or analog outputs (0/4 to 20 mA or 0 to 10 V).

- Binary input control.

- Soft-start function.

- 8 types of alarm functions.

- 24 V DC supply output to power transmitters and others.

- Signal retransmission.

- “Gain scheduling” and timer functions.

- Auto-tuning using the smart PID algorithm.

- Galvanically isolated inputs and outputs.

- Password protection.

- Fully programmable from the front panel.

- RS-485 Modbus RTU communication.

- IP rating IP 65.

- UC-820.

Air filter regulator P10

The P10 air filter regulators are used to remove both solid and liquid impurities from the air and to regulate the output pressure to the required value for general purpose pneumatic systems.

The filter bowl is transparent, allowing easy monitoring of the condensate level.

- Self relieving.

- Compact combined filter/regulator.

- 5 micron large surface area element.

- Manual and automatic condensate exhaustion are easier when there is no pressure.

- Pressure gauge D.42 x 1/8”

- Mounting bracket.

- Pneumatic systems.

- P10 – alluminium and polycarbonate.

- 1/4”.

- Female threaded ISO 7 Rp

Electro-pneumatic converters PC25

The ADCATrol PC25 is a compact device which converts a standard analog signal to a standard pneumatic signal, for the change-over between electrical controllers to pneumatic control valves, or from electrical measuring systems to pneumatic controllers.

The PC25 is a force balance device, which converts a 4 to 20 mA input signal into a proportional linear 0,2 to 1 bar output signal, with a respective supply pressure of 1,7 to 5 bar.

- Particularly compact design.

- Good dynamic response.

- Immune to mechanic vibrations.

- Low maintenance and low consumption.

- High reliability.

- Adjustable output measuring span.

- Pressure gauge on body

- Other output pressure ranges.

- PC25

- 1 /4"

- Female threaded NPT.

- In any position.

- See IMI – Installation and maintenance instructions.

Electro-Pneumatic positioners PI991

The ADCATrol PI991 is a digital intelligent electronically configurable positioner with communication capabilities, designed for mounting to pneumatic linear or rotary actuators. Communication protocols include analog (4 to 20 mA) with or without superimposed HART communication, PROFIBUS PA and FOUNDATION Fieldbus-H1.

The advanced diagnostic can be partially shown on the local LCD of the positioner or fully on a PC or a DCS workstation with a DTM based software (VALcare or Valve Monitor).

The PI991 also has the capability to control a Partial Stroke Test (PST) that offers to operators a tool to identify the trouble-proof function of ESD (Emergency Shut Down) valves.

- Low operating cost.

- Compact and flexible design.

- Easy to comission with user-friendly interface.

- Status and diagnostic messages displayed on LCD.

- Integrated mechanical position indicator.

- Mounting onto any linear or rotary actuator.

- Single or double acting.

- HART, Profibus PA or FOUNDATION Fieldbus-H1 communication.

- SIL3 certification.

- ATEX, FM, CSA and IECEx approvals.

- Stainless Steel housing for Offshore or Food and Beverage applications.

- Module for analog position feedback.

- Binary inputs and outputs.

- Digital position feedback with inductive switches (two or three-wire system).

- Digital position feedback with microswitches.

- Positioner with remote sensor.

- Sensors for supply air pressure and output pressure.

- Attachment kit for linear actuators acc. to IEC 534/NAMUR and rotary actuators acc. to VDI/VDE 3845.

- Connection manifold with gauges.

- Infrared Interface for wireless communication.

- Partial Stroke Test (PST) for Emergency Shut Down applications.

Electro pneumatic positioners PS100

The ADCATrol PS100 is a digital electronically configurable positioner designed for mounting to pneumatic linear or rotary actuators. It features a small and compact design with an excellent cost-performance ratio.

Fully automatic determination of the control parameters and adaptation to the final control element yield considerable time savings and an optimal control behaviour.

- Low operating cost.

- Compact and cost-effective.

- Easy to comission with user-friendly interface.

- Mounting onto any linear or rotary actuator.

- Negligible air consumption in stationary operation.

- Increased shock and vibration resistance, including steam hammers.

- Non-contact position detection with one-button initialization.

- Leakage compensation to ensure a constant actual value and to protect the actuator.

- Fast response in end positions ensures short positioning times and tight valves.

- Fast open/close end position behavior.

- ATEX, FM, CSA and IECEx approvals.

- Module for analog position feedback.

- Digital input and digital output signals.

- Attachment kit for linear actuators according to

- IEC 534/NAMUR and rotary actuators according to VDI/VDE 3845.

- Connection manifold with gauges.

- PS100

Electro-Penumatic positioners PE986

The ADCATrol PE986 is an electro-pneumatic positioner used for direct operation of pneumatic linear or rotary actuators by means of electrical controllers or control systems with a 4 to 20 mA, 2 to 10 V or split ranges output.

The positioner features a compact design and a modular construction which allows easy attachment of options such as limit switches, analog feedback modules, manifolds, volume boosters, amongst others.

- Compact and flexible design.

- Mounting onto any linear or rotary actuator.

- Single or double acting.

- Supply pressure up to 6 bar.

- Adjustable amplification and damping.

- Independent adjustment of stroke range and zero position.

- Resistant to vibration effect in all directions.

- ATEX approval (Ex ia).

- Module for analog position feedback.

- Digital position feedback with inductive switches (two or three-wire system).

- Digital position feedback with microswitches.

- Attachment kit for linear actuators acc. to IEC 534/NAMUR.

- Attachment kit with rotary adaptor for rotary actuators acc. to VID/ VDE 3845.

- Connection manifold with gauges.

- ATEX approval (Ex d): Version PE983.

- Volume boosters.

Pneumatic positioners PP981

The ADCATrol PP981 is a pneumatic positioner used for direct operation of pneumatic linear or rotary actuators by means of pneumatic controllers with a 0,2 to 1 bar proportional control signal. The positioner compares the output signal from a controller with the position feedback, and varies a pneumatic output signal to the actuator accordingly. The actuator position is therefore guaranteed for any controller output signal and the effects of varying differential pressure.

The positioner features a compact design and a modular construction which allows easy attachment of options such as limit switches, analog feedback modules, manifolds, volume boosters, amongst others.

- Compact and flexible design.

- Mounting onto any linear or rotary actuator.

- Single or double acting.

- Supply pressure up to 6 bar.

- Adjustable amplification and damping.

- Independent adjustment of stroke range and zero position.

- Resistant to vibration effect in all directions.

- ATEX approvals.

- Module for analog position feedback.

- Digital position feedback with inductive switches (two or three-wire system).

- Digital position feedback with microswitches.

- Attachment kit for linear actuators acc. to IEC 534/NAMUR.

- Attachment kit with rotary adaptor for rotary actuators acc. to VID/ VDE 3845.

- Connection manifold with gauges.

- Volume boosters.

Electro-pneumatic positioners TZIDC

The ADCATrol TZIDC is a digital intelligent electronically configurable positioner with communication capabilities designed for mounting to pneumatic linear or rotary actuators. It features a small and compact design, a modular construction, and an excellent cost-performance ratio.

Fully automatic determination of the control parameters and adaptation to the final control element yield considerable time savings and an optimal control behaviour.

- Low operating cost.

- Compact and flexible design.

- Easy to comission with user-friendly interface.

- Increased shock and vibration resistance with gearless sensor activation.

- Reliable and efficient, with integrated maintenance-friendly air filters.

- Automatic adjustment of control parameters during operation.

- Integrated mechanical position indicator.

- Wide operating temperature range (-40 to +85 ºC).

- Mounting onto any linear or rotary actuator.

- Single or double acting.

- HART, Profibus PA or FOUNDATION Fieldbus-H1 communication.

- ATEX, FM, CSA, GOST and IECEx approvals.

- SIL2 certification.

- Module for analog position feedback.

- Digital position feedback with inductive proximity switches.

- Digital position feedback with 24 V microswitches.

- Positioner with remote sensor.

- Attachment kit for linear actuators acc. to IEC 534/ NAMUR and rotary actuators acc. to VDI/VDE 3845.

- Connection manifold with gauges.

- PC adapters for communication.

- PC software for remote configuration and operation.

- TZIDC.

Limit switch boxes LSB1

The ADCATrol LSB1 is a limit switch box designed for mounting on pneumatic linear or rotary actuators serving as an interface between the valve and the control system.

Featuring a flexible and compact design, these devices are essential components in industrial and process control systems, playing a pivotal role in enhancing safety, efficiency, and control by providing accurate and real-time feedback on valve performance. This allows quick responses to changes in process conditions or emergencies while reducing the need for manual intervention.

The shaft of the LSB1 is connected to the shaft of the actuator and will turn when the actuator moves. The cams which are mounted on the shaft of the limit switch box will then activate the switches responsible for transmitting the electrical signals.

- Flexible, compact and easy to install.

- Highly configurable, with numerous options for switches.

- Can fit up to 4 switches.

- IP 67 protection.

- ISO 5211 mounting.

- Copper free housing for maximum corrosion and pitting protection.

- Aluminum or corrosion resistant stainless steel housings.

- Open/closed visual indicator (except stainless steel construction).

- ATEX approval.

- Attachment kit for linear actuators acc. to NAMUR (DIN IEC 60534-6-1).

- 1-3 slot type sensors and 1-2 cylindrical sensors available on request.

- Different indicator options, on request.

- LSB1

Stainless steel needle valves NV400

The NV400 is a series of high pressure needle valves designed for shut-off applications with steam and other industrial fluids.

The NV400B is a special version designed for use as a boiler water sample valve when connected to the bottom sample connection on a VPC TDS blowdown control valve.

- Complete stainless steel construction.

- High quality graphite packing.

- Version for oxygen service.

- Saturated steam, water, compressed air and other fluids compatible with the construction.

- NV400H; NV400B.

- 1/4" to 1/2".

- NV400H – Female threaded ISO 228.

- NV400B – Inlet: Female threaded ISO 228.

- Outlet: Comp. fitting 8S (M16 x 1,5).

- In any position.

Remarks:

- Other sizes, materials and connections available on request.

Gauge valves GC400

The GC400 gauge valves were designed for mounting of instruments such as pressure gauges, transmitters and switches. Throttling of the valve protects the connected instrument against pressure spikes. Complete valve shut-off and pressure release through the integrated vent plug allows safe instrument removal for replacement or calibration procedures.

- Integrated vent plug.

- Designed and tested according to DIN 16270.

- Version for oxygen service.

- Saturated steam, water, compressed air and other fluids compatible with the construction.

- GC400 – carbon steel.

- GC400I – stainless steel.

- ISO 228 G 1/2” (male x female).

Any position.

Remarks:

- Other sizes, materials and connections available on request.

Magnetic level indicators MLI

The MLI series of bypass type magnetic level indicators were designed for continuous level indication and/or control in ADCA ECRU units and other special SKID mounted packages.

The indicators can be equipped with multiple MSB reed switches for alarm purposes or a side mounted level transmitter for continuous level monitoring.

- Stainless steel construction.

- Minimal leak points as compared to sight glasses.

- No process media in contact with the indicator glass.

- Continuous measurement of levels, independent of physical and chemical changes of the media: flashing, foaming, bubble formation, etc

- MSB Magnetic bistable reed switches.

- MLI16

- Flanged EN 1092-1 PN 40.

- Flanged ASME B16.5 Class 300.

Level gauge valves LGC400

The LGC stainless steel level gauge valves are specially conceived to supervise the functioning and visualize the liquid level in pressure operated pumps, reservoirs and other equipment.

These valves are designed to be used with tubular glass, which can be supplied with the units.

- Stainless steel construction.

- Simple and cost-effective design.

- PTFE packing.

- Fitted with glass and protection guard.

- 1/4" bottom drain connection.

- LGC400 – stainless steel.

- 1/2" x 14 mm.

- Male threaded ISO 7 R.

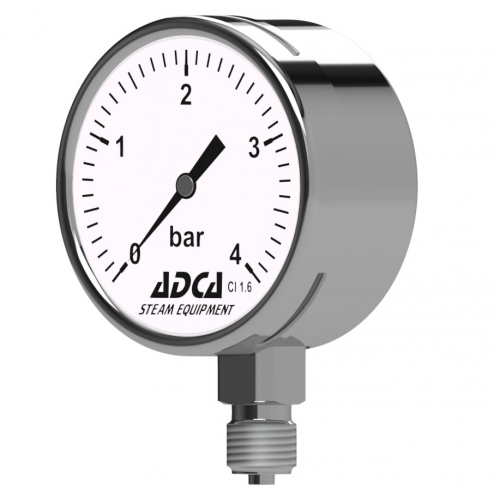

Pressure gauges MAN-100

The MAN-100 are reliable and cost-effective, general purpose bourdon tube pressure gauges designed for pressure measurement of liquid and gaseous media. They have a nominal size diameter of 100mm, units marked in bar and their casing is fully manufactured from stainless steel.

- Accuracy: 1% of full scale value.

- Designed according to EN 837-1.

- Bottom connection.

- Backside centric connection.

- Complete stainless steel construction

- Non-viscous and non-crystallizing liquids and gases compatible with copper alloy.

- MAN-100.

- ISO 228 G 1/2”.

MEASURING RANGES

- 0 – 2,5 bar; 0 – 4 bar; 0 – 6 bar; 0 – 10 bar;

- 0 – 16 bar; 0 – 25 bar; 0 – 40 bar.

Pressure gauges MAN-63

The MAN-63 are reliable general purpose bourdon tube pressure gauges designed for pressure measurement of liquid and gaseous media. These units have a size diameter of 63 mm, range marked in bar and are fully manufactured in stainless steel.

- Compact full stainless steel construction.

- Wetted parts in AISI 316Ti / 1.4571.

- Designed according to EN 837-1.

- Bayonet lock case with blow-out.

- Suitable to be filled with glycerine.

- Gases and liquids compatible with the construction.

- MAN-63R – radial connection.

- MAN-63A – axial connection.

- 1/4".

- ISO 228.

MEASURING RANGES

- -1 to 1,5 bar, 0 to 2,5 bar, 0 to 4 bar, 0 to 6 bar, 0 to 10 bar, 0 to 16 bar, 0 to 25 bar and 0 to 40 bar.

Pressure gauges MAN-40

The MAN-40 are reliable and cost-effective, general purpose bourdon tube pressure gauges designed for pressure measurement of liquid and gaseous media. They have a nominal size diameter of 40mm, units marked in bar, steel case and polycarbonate window screen.

- Accuracy: 1,6% of full scale value.

- Designed according to EN 837-1.

- Backside centric connection.

- Bottom radial connection.

- Complete stainless steel construction.

- Non-viscous and non-crystallizing liquids and gases compatible with copper alloy.

- MAN-40.

- ISO 228 G 1/4".

MEASURING RANGES

- 0 – 2,5 bar; 0 – 4 bar; 0 – 6 bar; 0 – 10 bar;

- 0 – 16 bar; 0 – 25 bar; 0 – 40 bar.

Bimetal thermometers TG90

The TG90 are general-purpose bimetal thermometers designed for temperature measurement in simple heating applications with liquid and gaseous media.

The unit has a nominal size diameter of 90 mm, units marked in Celsius degrees, casing manufactured in stainless steel, and includes a brass thermowell.

- Designed according to EN 13190.

- Accuracy class 2.

- Bottom radial or backside axial connection.

- Supplied with thermowell.

- Gases and liquids compatible with the construction.

- TG90R– radial connection.

- TG90A – axial connection.

- 1/2".

- 0 to 120 ºC.

- Others on request.

- ISO 228.

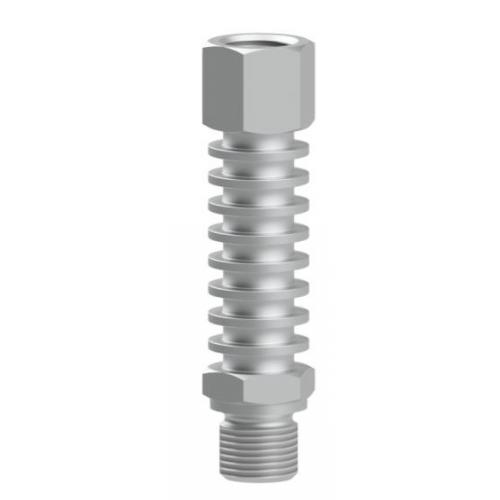

Gauge siphons GSC - GSU

The GS series pressure gauge siphons were designed to protect pressure gauges from the effects of sudden pressure surges and hot pressurized fluids.

They operate as cooling elements for liquids and gases in pressure measuring devices.

An isolation pressure gauge cock is recommended to be installed in combination with gauge siphons.

- Complete stainless steel construction

- Different types of connections

- Pressure gauge protection on steam, water, compressed air and other fluid systems compatible with the construction.

- G1/2” (male x female).

- ISO 228-1.

- GSC – vertical; GSU – horizontal.

LIMITING CONDITIONS

- 40 bar at 300 ºC; 110 bar at 110 ºC.

WEIGHT

- 0,34 kg.

- Coil – AISI 316L / 1.4404.

Gauge siphons GSV

The GSV series pressure gauge siphons have been designed to protect pressure gauges from the effect of rapid pressure surges and hot pressure fluids.

Specifically designed to replace the traditional “pigtail” and other coil design siphons where it is necessary to eliminate gauge whip and vibration. They operate as cooling elements for liquids and gases in pressure measuring devices.

An isolation pressure gauge cock is recommended to be installed in combination with gauge siphons.

- Complete stainless steel construction.

- Compact sturdy design, requires minimum space for installation.

- Different types of connections.

- Pressure gauge protection on steam, water, compressed air and other fluid systems compatible with the construction.

- GSV.

- ISO 228-1.

- Vertical

LIMITINNG CONDITIONS

- 63 bar at 400 ºC; 100 bar at 120 ºC.

WEIGHT

- 0,42 kg.

- AISI 316L / 1.4404