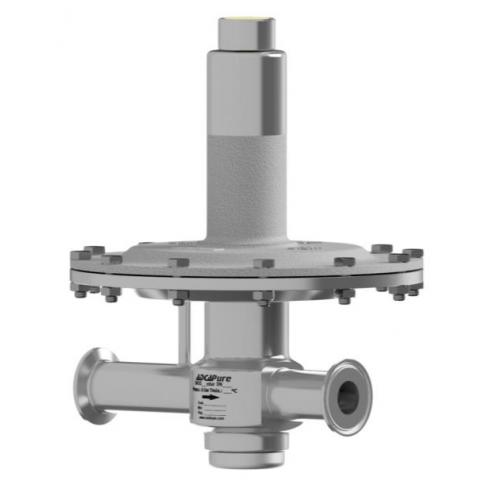

Sanitary tank blanketing regulators BKV2

(Low Pressure Vent Valve)

Tank blanketing valves are commonly used in tank storage systems to prevent and protect against explosions (by preventing flammable liquids from venting from the vessel), to control product contamination from external air that may fill the vapour space, to reduce evaporation losses (hence production losses), to reduce internal corrosion (caused by air and moisture) and to prevent a vacuum condition.

The blanketing process consists of blanketing the stored medium, usually a liquid, with a gas (usually N2).

- Compact design.

- Non-rising adjustment knob.

- FDA / USP Class VI compliant sealants.

STANDARD SURFACE FINISH

- Body and internal wetted parts: ≤ 0,51 micron Ra - SF1.

- Body exterior: ≤ 0.76 micron Ra - SF3.

- Cover: internal machined; external as cast iron.

- For other surface conditions, see IS PV20.00 E - Technical information.

- Ultrasonic cleaning.

- Leakage line connection.

- Dome loading.

- Top cap (adjusting screw with cover).

- Manometer connection on the body.

- External detection line connection.

- Vacuum cleaning.

- Hastelloy wetted parts.

- ATEX version.

- Compressed air, nitrogen and other gases compatible with construction.

- BKV2 - low pressure venting valve

- 1"; DN 25.

- 5 to 10 mbar; 10 to 50 mbar;

- 20 to 200 mbar; 50 to 500 mbar;

- 5 to 4000 mbar; 5 to 4000 mbar.

- 500 mbar; 5 to 4000 mbar (with dome).

- ASME BPE, DIN and ISO flanges.

- EN 1092-1 PN 16 flange.

- Others on request.

- Vertical installation recommended, to allow drainage, or horizontal as close to the process as possible in order to prevent long pipe sections and flow restrictions.

- See IMI – Installation andmaintenance instructions.

- Assembling and packaging in a clean room certified according to ISO 14644-1.

- The product is end capped and sealed with recyclable thermo-shrinkable plastic film, to avoid contamination.