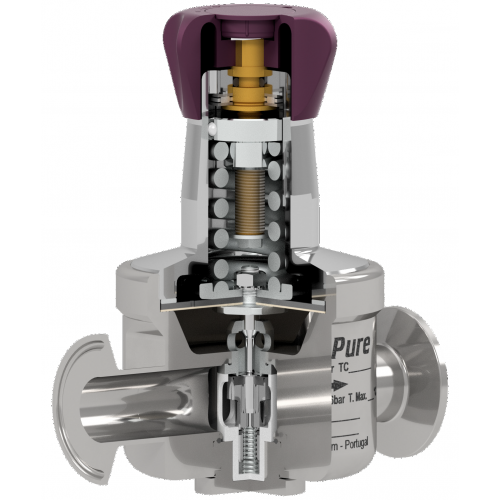

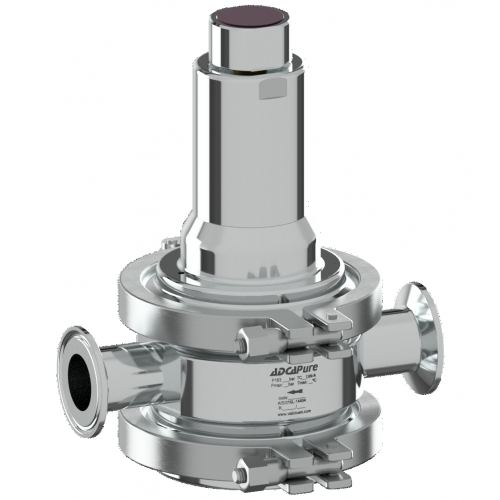

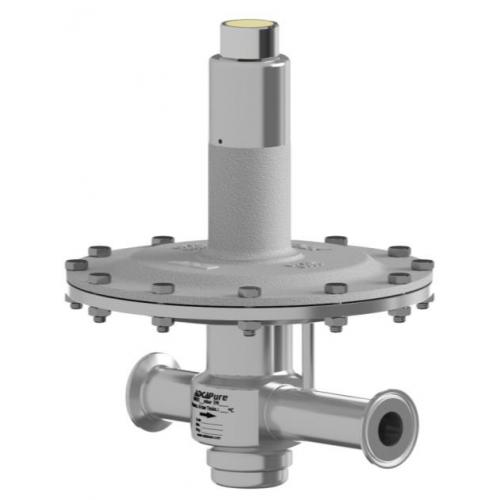

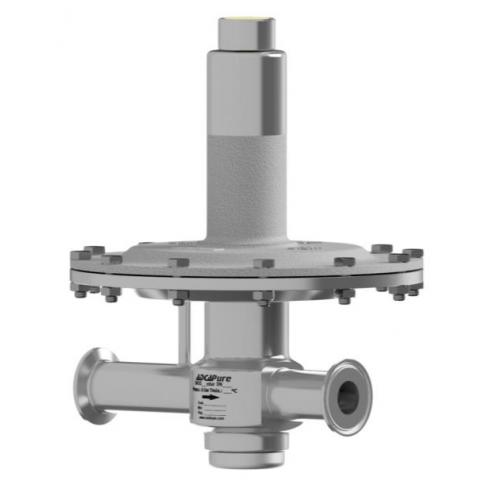

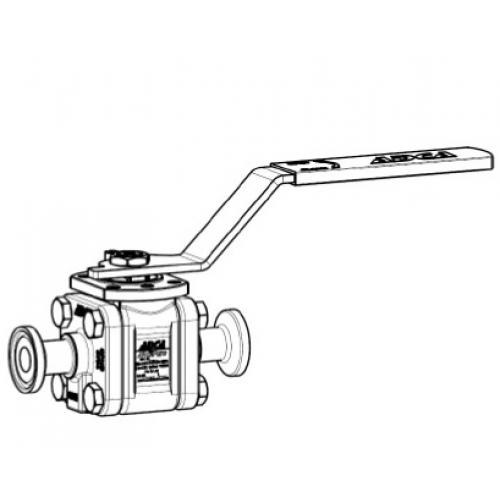

The ADCAPure P147 valve is a series of pilot operated pressure reducing valves.

These regulators, available in spring-loaded or dome-loaded versions, are designed for use with clean air, nitrogen, carbon dioxide, carbon dioxide, nitrous

for use with clean air, nitrogen, carbon dioxide, oxygen, argon and other gases compatible with the valve's materials of construction and design. Specifically designed for high purity gas systems found in pharmaceutical, cosmetic, fine chemical and food and beverage processes.