- Low pressure drop

- Simple and compact design

- Dimensions according to DIN 3202 part 3-K4

Check Valves

Non-return valves DN08-50 RT25

The RT25 disc check valve, made entirely of stainless steel, has a compact design and is especially suitable for use with steam and condensate. Threaded connections DIN or ANSI wafer type.

- Soft seat in EPDM, NBR, Viton or PTFE

- Inconel springs

- Saturated steam, water and other gases compatible with the construction.

- RT25 - stainless steel.

- 1/4" a 2".

- ISO 7 Rp or NPT female threads.

- Horizontal or vertical installation.

- See IMI - Installation and maintenance instructions.

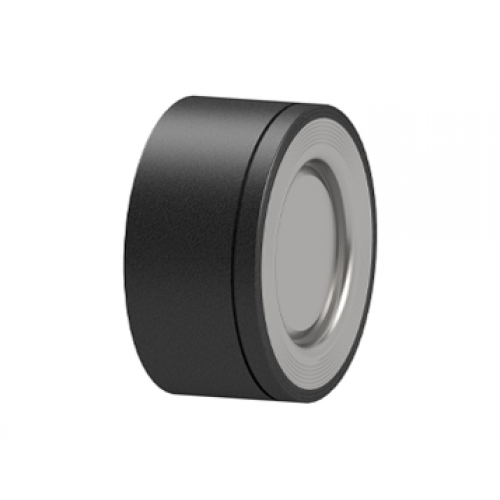

Wafer type non return valve RD40 DN15 – DN100

The RD40 wafer disc check valve, made entirely of stainless steel, has a compact design and is especially suitable for use with steam and condensate. DIN or ANSI wafer connection.

- Low pressure drop

- Simple and compact design

- Dimensions according to DIN 3202 part 3-K4

- Soft seat in EPDM, NBR, Viton or PTFE

- Inconel springs

- Saturated steam, water and other gases compatible with the construction.

- RD40 - stainless steel.

- 1/2" to 4"; DN 15 to DN 100.

- Assembly between flanges according to EN 1092 or ASME.

- Horizontal or vertical installation.

Stop Valves

Three piece ball valves M3i5

The M3i5 series three-piece ball valves are isolation valves designed for use with steam, condensate and other gases and liquids compatible with their construction.

The valve is not designed as a control valve and should be used only as an isolation valve.

- Full bore floating ball design.

- Can be repaired without removal from the pipeline.

- Bi-directional.

- Non-ejecting stem.

- Anti-static device.

- PN100 rating

- Different materials for the seats

- Steam, gases and liquids compatible with the construction.

- M3i5 - stainless steel.

- 1/2" a 2".

- Female thread ISO 7 Rp or NPT.

- Socket weld (SW) ASME B16.11.

- See IMI - Installation and maintenance instructions.

Three piece ball valves M3i1

The M3i1 series three-piece ball valves are isolation valves designed for use with steam, condensate and other gases and liquids compatible with their construction.

The valve is not designed as a control valve and should be used as an isolation valve only.

- Full bore floating ball design.

- Can be repaired without removal from the pipeline.

- Bi-directional.

- Non-ejecting stem.

- Anti-static device.

- PN100 rating

- Different seat materials

- Steam, gases and liquids compatible with the construction.

- M3i1 - stainless steel.

- 3/8" to 2".

- Female thread ISO 7 Rp or NPT.

- Socket weld (SW) ASME B16.11.

- See IMI - Installation and maintenance instructions.

Three pieces ball valves M3S1

The M3S1 3-piece ball valve is a shut-off valve designed for use on steam, condensate and other gases and liquids compatible with materials of construction. This type of valve is not designed as a control valve and should be used only as a shut-off or isolation valve, fully open or closed. Threaded or SW weld connections

- Full bore design.

- Floating ball

- Bidirectional

- Can be serviced without removing from the line

- Non-ejecting shaft

- Anti-static device

- Different sealing materials.

- Flame retardant design.

- Steam, gases and liquids compatible with construction.

- M3S1 - Zinc plated carbon steel. PN100.

- 1/2" a 2".

- Female BSP ISO 7/1 Rp (BS21).

- NPT according to ANSI B1.20.1.

- SW - Socket weld per ANSI B16.11.

- BW - Butt weld per ANSI B16.25.

- See IMI - Installation and maintenance instructions.

Wafer ball valves MWS1 – MWi1

The MWS1 series wafer ball valves are isolating valves designed for use on steam, condensate and other gases and liquids compatible with the construction.

The valve is not designed as a control valve and should be used only as an isolating valve, fully open or fully closed.

Connections are flanged wafer.

- Full pitch design.

- Floating ball

- Bidirectional

- Non-ejecting shaft

- Anti-static device

- ISO 5211 mounting.

- Different sealing materials.

- Lever extension for insulation

- Steam, gases and liquids compatible with the construction.

- MWS1 - Carbon steel.

- MWi1 - Stainless steel.

- DN 15 to DN 150.

- Flanged EN1092-1 PN16.

- See IMI - Installation and maintenance instructions.

Manual actuator with return to fail-safe position SRH

The SRH consists of a spring box which, once mounted, switches the ball valve to a safe position (closed or open), as soon as the operator releases its handle

- Clockwise spring action.

- Lockable as standard.

- Weatherproof sealed spring housing.

- Sealed to IP 65

- Counterclockwise spring action.

- Padlock

- Fail-safe operation for quarter-turn valves.

- SRH1 - AISI 304 stainless steel.

- Actuator and fixings according to ISO standard.

Bronze globe valve GV32B

Bronze break valve series GV32B, with threaded connections, for use in steam, water, oil or compressed air lines.

- Rising spindle

- High quality PTFE packing

- Replaceable PTFE seated disc

- Saturated steam, condensate, oil-water, compressed air and other fluids compatible with the construction.

- GV32B

- 1/2" a 2".

- Female thread ISO7/1 Rp (BS21).

- Body design conditions: PN32.

- 198ºC at 14 bar.

- 100ºC at 32 bar.

Bellows sealed stop valves VF20

The VF20 series is a maintenance-free, non-rising stem, bellows-type globe shut-off valve for in-line mounting. It is especially recommended for use in steam, gas, liquid, condensate, thermal oil and water systems.

- Double-walled bellows designed for high durability

- Maintenance free

- Safety packing

- Position indicator

- Lubricator

- Parabolic plug for throttling applications.

- Soft PTFE seal for applications up to 180°C.

- Group 2 fluids compatible with construction.

- VF20 - cast iron.

- DN 15 to DN 200.

- Flanged EN 1092-2 PN 16.

- See IMI - Installation and maintenance instructions

Bellows sealed stop valves VF40

The VF series is a maintenance-free, non-rising stem, bellows-type globe shut-off valve for in-line mounting. It is especially recommended for use in steam, gas, liquid, condensate, thermal oil and water systems.

- Double-walled bellows designed for high durability

- Maintenance free

- Safety packing

- Position indicator

- Lubricator

- Anti-static device

- Parabolic plug for throttling applications

- Group 2 fluids compatible with the construction

- VF40S - carbon steel.

- VF40I - stainless steel.

- DN 15 to DN 200.

- With flanges EN 1092-1 PN 40.

- See IMI - Installation and maintenance instructions.

Humidity Separators

Threaded steam droplet separator DN15-50 S16S

The S-16 centrifugal droplet separator removes moisture from the fluid in the steam and compressed air lines. Steam and compressed air pass through the separator and, as a result of centrifugal forces, particles of higher specific gravity such as water and oil or small droplets of suspended moisture as well as dirt or scale are separated. The condensate collected in the lower part of the separator must be discharged by means of a condensate drain or compressed air eliminator.

- Various installation possibilities

- No moving parts

- Maintenance-free design.

- Flanged condensate connection.

- Steam, compressed air and other gases.

- S16S - carbon steel

- 1/2" a 2".

- Female thread ISO 7 Rp or NPT.

- Always with condensate discharge downwards.

- See IMI -

Stainless steel threaded steam droplet separator DN15-150 S16SS

The S-16 centrifugal droplet separator removes moisture from the fluid in the steam and compressed air lines. Steam and compressed air pass through the separator and, as a result of centrifugal forces, particles of higher specific gravity such as water and oil or small droplets of suspended moisture as well as dirt or scale are separated. The condensate collected in the lower part of the separator must be discharged by means of a condensate drain or compressed air eliminator.

Threaded connections. Made of stainless steel

- Different installation possibilities

- No moving parts

- Maintenance free design.

- Flanged condensate connection

- Steam, compressed air and other gases.

- S16SS - stainless steel.

- 1/2" a 2".

- Female thread ISO 7 Rp or NPT.

- Always with condensate discharge downwards.

- See IMI -

Humidity separators PN16-40 DN15-300 S25/S

The S25 series centrifugal separators remove moisture from steam and compressed air pipelines. Steam and compressed air pass through the separator and, as a result of centrifugal forces, impacts and vortex effects, particles with a heavier specific gravity, such as water and oil droplets, suspended moisture, dirt and scale are separated from the fluid.

Condensate collected at the bottom of the separator must be drained automatically by means of a suitable steam or compressed air trap.

- Various installation possibilities.

- No moving parts.

- Maintenance-free design.

- Flanged connection for condensate.

- Steam, compressed air and other gases.

- S25/S - carbon steel

- DN 15 to DN 300.

- With flanges EN 1092-1 PN 16 or PN 40.

- ASME B16.5 Class 150 or 300 flanges on request.

- Female thread ISO 7 Rp or NPT on request.

- Standard flanges PN 16 DN 65 are supplied with 4 holes. 8 holes, according to EN 1092, on request.

- See IMI - Installation and maintenance instructions.

Humidity separators PN63 DN15-300 S25/S

The S25 series centrifugal separators remove moisture from steam and compressed air pipelines. Steam and compressed air pass through the separator and, as a result of centrifugal forces, impacts and vortex effects, particles with a heavier specific gravity, such as water and oil droplets, suspended moisture, dirt and scale are separated from the fluid.

Condensate collected at the bottom of the separator must be drained automatically by means of a suitable steam or compressed air trap.

- Various installation possibilities.

- No moving parts.

- Maintenance-free design

- Flanged connection for condensate.

- Steam, compressed air and other gases.

- S25/S - carbon steel

- DN 15 to DN 200

- Flanged EN 1092-1 PN 63.

- Flanged ASME B16.5 Class 600 on request.

- Socket welded (SW) ASME 16.11.

- See IMI - Installation and maintenance instructions.

Humidity separators stainless steel DN15-300 S25/SS

The S25 series centrifugal separators remove moisture from steam and compressed air pipelines. Steam and compressed air pass through the separator and, as a result of centrifugal forces, impacts and vortex effects, particles with a heavier specific gravity, such as water and oil droplets, suspended moisture, dirt and scale, are separated from the fluid.

The condensate collected at the bottom of the separator must be drained automatically by means of a suitable steam or compressed air trap.

- Various installation possibilities.

- No moving parts.

- Maintenance-free design

- Flanged condensate connection.

- Steam, compressed air and other gases.

- S25/SS - stainless steel.

- DN 15 to DN 300.

- With flanges EN 1092-1 PN 16 or PN 40.

- ASME B16.5 Class 150 or 300 flanges on request.

- Female thread ISO 7 Rp or NPT on request.

- Always with condensate discharge facing downwards.

- See IMI - Installation and maintenance instructions

Droplet separator special run S25S HV-VH

The centrifugal separators of the S25 HV and VH series remove moisture from steam and compressed air lines. The steam and compressed air pass through the separator and, as a result of the centrifugal forces and vortex effects, particles with a higher specific gravity such as water and oil droplets, suspended moisture, dirt and scale are separated from the fluid. Flanged connections

The condensate collected at the bottom of the separator must be automatically drained by means of a suitable steam or compressed air trap.

- Different installation possibilities

- No moving parts

- Maintenance-free design.

- Steam, compressed air and other gases.

- S25/S HV or VH - carbon steel

- DN 15 to DN 200.

- With flanges EN 1092-1 PN 16 or PN 40.

- ASME B16.5 Class 150 or 300 flanges on request.

- Female thread ISO 7 Rp or NPT on request

- Always with condensate discharge facing downwards.

- See IMI - Installation and maintenance instructions

Humidity separator with filter DN15-100-SF251

The SF251/S series centrifugal droplet separator removes moisture from steam and compressed air pipes. Steam and compressed air pass through the separator and, as a result of centrifugal forces, impact and vortex effects, particles with a heavier specific gravity, such as water and oil droplets, suspended moisture, dirt and scale are separated from the fluid.

Condensate collected at the bottom of the separator must be drained automatically by means of a suitable steam or compressed air trap.

- Various installation possibilities

- No moving parts

- Stainless steel filtration mesh

- Threaded condensate connection.

- Special designs made to measure.

- Steam, compressed air and other gases .

- SF251/S - carbon steel.

- 1/2" to 4"; DN 15 to DN 100.

- Flanged EN 1092-1 PN 16 or PN 40.

- Flanged ASME B16.5 Class 150 or 300 on request.

- Always with condensate discharge facing downwards.

- See IMI -

Humidity separators horizontal PN16-40 DN15-150 SH25S

The SH25S horizontal centrifugal droplet separator of the SH family removes moisture from the fluid in the steam and compressed air lines. Steam and compressed air pass through the separator and, as a result of centrifugal forces, particles of higher specific gravity such as water and oil or small droplets of suspended moisture as well as dirt or scale are separated. The condensate collected in the lower part of the separator must be discharged by means of a condensate drain or compressed air eliminator.

- Different installation possibilities

- No moving parts

- In-line design

- Steam, compressed air and other gases.

- SH25S - carbon steel.

- 1/2" to 6"; DN 15 to DN 150.

- Flanged EN 1092-1 PN 16 or PN 40.

- Flanged ASME B16.5 Class 150 or 300.

- Horizontal with condensate discharge downwards.

- See IMI - Installation and maintenance instructions.

Baffle separators PN16-40 DN15-300 S30

The steam and compressed air pass through the separator and, as a result of the effects of expansion, impact and swirling, particles of higher specific gravity, such as water and oil droplets, suspended moisture, dirt and scale, are separated from the fluid.

The condensate collected at the bottom of the separator must be automatically drained by means of a suitable steam or compressed air trap.

- Various installation possibilities.

- No moving parts.

- Maintenance free design

- Flanged connection for condensate.

- Steam, compressed air and other gases.

- S30/S - carbon steel, baffle design

- DN 15 to DN 300.

- Flanged EN 1092-1 PN 16 or PN 40.

- Flanged ASME B16.5 Class 150 or 300 on request.

- Female thread ISO 7 Rp or NPT on request

- Always with condensate discharge facing downwards.

- See IMI

Centrifugal air and dirt separators for liquid systems DN32-300 AS - ASF

The AS series centrifugal air and dirt separators are designed for use in the flow line of a hydronic heating or cooling system. Operation is based on the principle of centrifugal force, rather than on low velocity separation, which offers the advantage of efficient separation in a smaller form factor.

The internal filter protects against any dirt present in the system such as sand, welding residues and other foreign matter. The internal filter has a special advantage compared to pipe filters, as the dirt is removed from the water flow and collected at the bottom of the unit, preventing pressure losses

- No moving parts.

- Integrated filter.

- Maximum separation efficiency in minimum space

- Different connections and power ratings upon request.

- To remove air and dirt in hydronic heating, cooling and pumping systems.

- AS/S - carbon steel body

- AS/SS - stainless steel body.

- AS/SF - carbon steel with filter.

- AS/SSF - stainless steel with filter.

DN 32 to DN 300.

- EN 1092-1 PN 16 flanges.

- ASME B16.5 Class 150 flanges.

- Standard flanges PN 16 DN 65 are supplied with 4 orifices. 8 orifices, according to EN 1092, on reques

- Female thread ISO7 Rp or NPT, on request.

- AS separators should be installed at the points of highest temperature and lowest pressure, where solubility is lowest.

- Ideally, they should be installed downstream of boilers or heat exchangers, upstream of chillers and pump suction.

- Horizontal installation, always with the drainage discharge downwards.

- The installation of an ADCA AE series air eliminator is recommended to eliminate the air.

Sight glasses

Single Window Sight Glass Brass DN15-25 SW12

The SW12 is a series of single sight glasses, specially designed for installation downstream of steam traps to check for live steam leaks or blockages.

These devices can also be used to monitor flow conditions in other applications, especially in piping with liquid media. applications, especially in piping with liquid media.

- Compact and economical.

- Single window design.

- Borosilicate glass

- Mica shield discs for steam use.

- Condensate lines and others

- SW12 - brass.

- 1/2" a 1".

- Female thread ISO 7 Rp.

- Horizontal or vertical installation.

- See IMI - Installation and maintenance instructions.

Double window singht glasses DN15-50 DW40S

To check the correct functioning of a condensate drain and to avoid live steam leaks and consequently high energy losses, the installation of a sight glass downstream of the drain is recommended. The DW40S double glass sight glass has been specially designed for this particular application. Threaded or flanged connections.

- Compact.

- Double window design.

- Borosilicate glass.

- Mica shield discs for steam use.

- Condensate lines and others.

- DW40S - carbon steel.

- 1/2" to 2"; DN 15 to DN 50.

- Female thread ISO 7 Rp or NPT.

- Flanged EN 1092-1 PN 40.

- Flanged ASME B16.5 Class 150 or 300.

- Horizontal or vertical installation.

- See IMI - Installation and maintenance instructions

Double window sight glass stainless steel DN15-50 DW40SS

The DW40SS is a series of double glazed sight glasses specially designed for installation downstream of steam traps for the purpose of monitoring their monitoring their operation, such as checking for live steam leaks or blockages.

These devices can also be used to monitor flow conditions in other flow conditions in other applications, especially in piping with liquid media.

- Compact.

- Corrosion resistant stainless steel body.

- Double glass design.

- Borosilicate glass.

- Mica shield discs for steam use

- Condensate lines and others.

- DW40SS - stainless steel.

- 1/2" to 2"; DN 15 to DN 50.

- Female thread ISO 7 Rp or NPT.

- Flanged EN 1092-1 PN 40.

- Flanged ASME B16.5 Class 150 or 300.

- Horizontal or vertical installation.

- See IMI - Installation and maintenance instructions

Sight Checker Stainless Steel DN15-25 SCKI

SCKi sight glasses function as sight glasses and check valves.

These devices are designed for installation downstream of steam traps to monitor their performance, while functioning as check valves to prevent condensate backflow.

- Stainless steel construction.

- Threaded connections.

- Mica protection discs for use with steam

- Condensate lines, downstream of steam traps.

- SCKi - stainless steel.

- 1/2" a 1.

- Female thread ISO 7 Rp or NPT.

- Horizontal or vertical installation (bottom to top).

- See IMI - Installation and maintenance instructions.

- The SCKi must be installed at a minimum distance of 1 metre from the siphon, in order to protect the glass from pressure or thermal shocks.

Double window sight glasses DW12G

The DW12 is a series of double-glazed sight glasses specially designed for installation downstream of steam traps to check for live steam leaks or blockages.

These devices can also be used to monitor flow conditions in other applications, especially in pipelines with medium

flow conditions in other applications, especially in pipelines with liquid media

- Compact and economical.

- Double window design.

- Borosilicate glass.

- Condensate lines and others (see table "Body conditions")

- Condensate lines and others (see table "Body conditions").

- DW12G - cast iron.

- DW12SS - stainless steel.

- DN 15 to DN 150.

- Flanged EN 1092-1/-2 PN 16.

- Horizontal or vertical installation.

- See IMI.

Filters

Pipeline Y strainers IS140

IS140 Y type filters are applicable to all types of steam, water and oil systems.

Their purpose is to protect traps, regulating valves, pipes, etc. from dirt and impurities, which are often the cause of damage and consequent loss of energy and consequent loss of energy in fluid systems.

- Sieves with different degrees of filtration

- Drain plug or drain valve in the filter cover.

- Saturated steam, water, oils, air and other fluids compatible with the materials of construction.

- IS140S - cast steel.

- IS140i - stainless steel.

- 1/2" a 2".

- 0.8 mm aperture.

- ISO 7 Rp or NPT female threads.

- Horizontal or vertical installation downstream.

- See IMI - Installation and maintenance instructions.

Pipeline Y strainers IS116

The IS116 Y type filter, made of forged carbon steel, is applicable to all types of steam, compressed air, oil, etc. lines at high pressure and temperature. Its purpose is to protect the equipment installed in these lines from dirt, such as traps, regulation valves, etc., which can be affected, causing their premature replacement due to malfunctioning and consequently generating energy losses

- Filter cover with drain plug.

- Sieves with different degrees of filtration

- Drain plug or drain valve in the filter lid.

- Saturated steam, water, oil, oil, air and other fluids compatible with the materials of construction.

- IS116 - forged steel.

- 1/2" to 2"; DN 15 to DN 50.

- 0,8 mm opening.

- Others on request.

- Female thread ISO 7 Rp or NPT.

- With flanges EN 1092-1 PN 40, PN 63 or PN 100.

- Flanged ASME B16.5 Class 150, 300 or 600.

- Socket weld (SW) ASME 16.11.

- Horizontal or vertical installation downstream.

- See IMI - Installation and Maintenance Instructions

Pipeline strainers DN15-300 IS16F

The IS16F type Y filter, made of cast iron, is applicable to all types of steam, compressed air, oil, etc. lines. Its purpose is to protect the equipment installed in these lines from dirt, such as traps, regulation valves, etc., which can be affected, causing their premature replacement due to malfunctioning and consequently generating energy losses.

- Different sieve opening sizes.

- Drain plug or drain valve in the filter cover.

- Group 2 fluids compatible with the materials of construction (see "Table of body limit conditions").

- IS16F - cast iron.

- DN 15 to DN 300.

- 1 mm filtration degree - up to DN 50.

- Grade of filtration 1,25 mm - from DN 65 to DN 80.

- Grade of filtration 1.6 mm - from DN 100 to DN 300.

- EN 1092-2 PN 16 flanges.

- Horizontal or vertical downward installation.

- See IMI - Maintenance and installation instructions

Pipeline T Strainers DN25-100 IS40T (EN)

IS40T cast steel T-filters are applicable to all types of steam, water, oil and air systems. Their purpose is to protect steam traps, regulating valves, pressure reducing valves, pipes, etc. from dirt, which is often the cause of damage and consequently loss of energy in fluid systems.

Flanged EN 1092-1 PN40

- Different mesh opening sizes.

- Drain plug or drain valve in the filter cover.

- Saturated steam, water, oil, oil, air and other compatible fluids

- IS40TS - Carbon steel.

- IS40TI - Stainless steel.

- DN 15 to DN 100.

- 0.5 mm opening up to DN 25.

- 1,5 mm opening from DN 32 to DN 80.

- 2 mm opening DN 100.

- Flanged EN 1092-1 PN40.I

- Horizontal or vertical installation.

- See IMI – Installation and maintenance instructions

Pipeline T Strainers DN25-100 IS40T (ASME)

IS40T cast steel T-filters are applicable to all types of steam, water, oil and air systems. Their purpose is to protect steam traps, regulating valves, pressure reducing valves, pipelines, etc. from dirt, which is often the cause of damage and consequently loss of energy in fluid systems.

ASME B16.5 Class 150 or 300 connections

- Different mesh opening sizes.

- Drain plug or drain valve in the filter cover.

- Saturated steam, water, oil, oil, air and other fluids compatible with materials of construction.

- IS40TS - carbon steel.

- 1" to 4".

- 0.5 mm opening - 1".

- 1.5 mm opening - 11/2" to 3".

- 2 mm aperture - 4".

- ASME B16.5 Class 150 or 300 flanges.

- Horizontal or vertical installation.

- See IMI - Installation and Maintenance Instructions.

Vacuum Breakers

Vacuum breaker VB21-VB21M

VB21 - VB21 vacuum breakers are simple and reliable devices that automatically relieve or "break" an unwanted vacuum condition by restoring atmospheric pressure.

This equipment is particularly suitable for small to medium volume steam heated equipment such as heat exchangers, heating coils, accumulators, jacketed boilers, etc

- Saturated and superheated steam.

- VB21 - female thread.

- VB21M - male thread

- 1/2" x 1/8".

- System: 1/2" vertical connection.

- Air inlet: horizontal connection 1/8".

- VB21 - female thread ISO 7 Rp or NPT.

- VB21M - male thread ISO 228 G

- Vertical installation with angled connection.

- See IMI - Installation and maintenance instructions

- 13 bar at 400 ºC.

- 21 bar at 220 ºC.

Vacuun breaker VB16

VB16 vacuum breakers are simple and reliable devices that automatically relieve or "break" an unwanted vacuum condition by restoring atmospheric pressure.

This device is particularly suitable for small and medium volume steam heated units such as heat exchangers, heating coils, jacketed kettle calorifiers, steam boilers etc.

- Stainless steel inlet baffle.

- Saturated steam and other gases compatible with the construction.

- VB16 - stainless steel.

- 1/2" a 1".

- ISO 228 G male thread.

- Vertical installation.

- See IMI - Installation and installation and maintenance instructions.

- 12 bar at 150 ºC.

- 16 bar at 120 ºC.

Vacuum breakers VB17

The VB17 is a series of vacuum breakers designed to automatically relieve or “break” an unwanted vacuum condition. Applications include venting and vacuum limiting in pipelines, vessels, heat exchangers, autoclaves, steam boilers and other machines. These valves should not be used as vacuum control valves.

The device is kept close by means of a spring-loaded valve and the pressure which acts on the underside of the plug. When pressure drops below the adjusted set pressure, unbalancing of forces causes the valve to open, allowing atmospheric air to enter the system. With raise in differential pressure results an increase in valve stroke and air flow.

The units are available with an optional lift indicator to signal in case of opening, for monitoring or contamination detection purposes.

- Metallic wetted parts machined from 316L stainless steel bar stock.

- Regulating ranges from -0,05 to -0,95 bar.

- Compact design with easy access for cleaning and inspection.

- Lift indicator.

- Different soft sealings for vapours and gases.

- Degreasing.

- Other construction materials.

- Steam and other vapours and gases compatible with the construction.

- VB17

- 1/2" to 2" – DN 15 to DN 50.

- Male threaded ISO 228 G or NPT.

- Flanged EN 1092-1 PN 16 (threaded flange).

- Flanged ASME B16.5 Class 150 (threaded flange).

- Vertical installation.

- See IMI – Installation and maintenance instructions.

Shell and Tubes Heat Exchangers

Shell and tube heat exchangers STS

The ADCA ST series steam to water shell and tube heat exchangers are shorter and lighter than the alternative shell and tube exchangers manufactured with smooth pipes. The use of extruded low fin tube has

the advantage that it can improve the external surface and thermal performance.

(Steam to water – Vertical installation)

- Corrosion-resistant stainless steel low finned tube bundle and shell construction.

Straight tubes for easy cleaning. - Expansion bellow in the shell, avoiding excessive tube stresses caused by thermal expansion and contraction.

- Horizontal installation (STSH).

- Steam, water, hot condensate and other fluids compatible with the construction.

- STSV – vertical installation.

- Vertical or horizontal (different condensate heads execution).

- See IMI – Installation and maintenance instructions.

- Steam pressure and temperature.

- Inlet and outlet water temperature.

- Water mass flow or heat exchanged.

Shell and Tube Heat Exchanger STH

The ADCA-ST series shell and tube heat exchangers are shorter and lighter than shell and tube heat exchangers made of plain tubes. The use of extruded tubes has the advantage of increasing the external surface area and improving the thermal efficiency.

(Steam to water – Horizontal installation)

- Corrosion resistant stainless steel tube bundle.

- Straight tubes for easy maintenance and cleaning operations.

- Floating head to avoid stresses caused by thermal expansion and contraction.

- Steam, water, hot condensate and other fluids compatible with the construction.

- STH/S - carbon steel housing.

- STH/SS - all stainless steel.

- Flanged EN 1092-1 PN 16.

- Flanged ASME B16.5 Class 150.

- Female thread ISO 7 Rp or NPT.

REQUIRED DATA

- Inlet and outlet water temperature.

- Mass flow rate of water or heat exchanged

- It can be installed on the floor, on the wall or hung from the ceiling.

- Steam flows through the inside of the pipes and process water flows through the outside.

- See IMI - Installation and Maintenance Instructions

- Steam pressure and temperature.

Shell and Tube Heat Exchanger STV

The ADCA-ST series shell and tube heat exchangers are shorter and lighter than shell and tube heat exchangers made with plain tubes. The use of extruded tube has the advantage of increasing the external surface area and improving the thermal performance.

(Steam to water – Vertical installation)

- Corrosion resistant stainless steel tube bundle.

- Straight tubes for easy maintenance and cleaning operations.

- Floating head to avoid stresses caused by thermal expansion and contraction.

- Horizontal installation (STSH)

- Steam, water, hot condensate and other fluids compatible with the construction.

- STV/S – carbon steel shell.

- STV/SS – completely in stainless steel

- Flanged EN 1092-1 PN 16.

- Flanged ASME B16.5 Class 150.

- Female threaded ISO 7 Rp or NPT.

- Wall mounting or floor (needs special supports).

- Steam runs inside the tubes and process water outside.

- See IMI – Installation and maintenance instructions.

- Steam pressure and temperature.

- Inlet and outlet water temperature.

- Mass flow rate of water or heat exchanged.

Heating coil for steam SERIE-R

The ADCA-R series of tubular steam heating coils are shorter and lighter tubular heating coils made of smooth tubes. The use of extruded tubing has the advantage of increasing the external surface area and improving thermal performance.

- Corrosion resistant stainless steel tube bundle.

- Straight tubes for easy maintenance and cleaning operations.

- Floating head to avoid stresses caused by thermal expansion and contraction.

- Special designs.

- Special designs.

- Steam, water, hot condensate and other fluids compatible with the construction.

- R5, R6, R8 and R10.

- With EN 1092-1 or ANSI flanges.

- Bolted on request.

- Horizontally in horizontal vessels.

- Steam circulates inside the tubes and process water circulates outside.

Plate Heat Exchangers

Plate late heat exchangers PAT

The ADCATHERM PAT series of plate and gasket heat exchangers consist of a variable number of plates, clamped between a fixed and a movable plate, all mounted on a movable frame

- Corrosion-resistant stainless steel plates with high heat transfer efficiency (much higher K-values compared to shell and tube design)

- Less space required for installation

- Low liquid content

- Additional capacity available by adding plates

- Special designs and materials (titanium, special alloys, lined connections, etc.).

- Thermal insulation.

- Stainless steel frame.

- Steam, water, hot condensate and other fluids compatible with the construction.

- PAT00 to PAT30.

- PATL00 to PATL50.

- PATR00 to PATR50.

- Female thread ISO 228 or NPT.

- Flange EN 1092-1 PN 10 or ASME B16.5 Class150.

- Others on request.

- Vertical installation. Horizontal installation

- Horizontal on request.

- See IMI - Installation and maintenance instructions.

Flash Vessel

Flash Vessel RV

The flash tank is the main component of any flash or revaporized steam recovery system.

It can be used in all steam plants where high pressure condensate is reduced to a lower pressure generating revaporized steam; this steam can be used in low pressure process equipment or for energy savings.

Connections are flanged or special executions on request.

- Various installation possibilities, special sizes and types (available on request).

- Complete stainless steel construction.

- Installation brackets on the body (without support

- High pressure condenser.

- Boiler blowdown heat recovery systems.

- RV...A/S; RV...L/S - carbon steel.

- RV...A/SS; RV...L/SS - stainless steel.

- (A - angle; L - in-line connections).

- RV06, RV08, RV12, RV16 and RV18.

- EN 1092-1 PN 16 flange.

- Special flanges on request.

- Vertical installation with flash steam outlet at the top.

- Horizontal condensate inlet and vertical outlet (RV...A).

- Horizontal condensate inlet and outlet (RV...L).

- See IMI - Installation and maintenance instructions

Flash Vessel RVST (With inbuilt steam trap)

The flash tank is the main component of any flash or revaporized steam recovery system.

It can be used in all steam plants where high pressure condensate is reduced to a lower pressure generating revaporized steam; this steam can be used in low pressure process equipment or for energy saving.

Connections are flanged or special executions on request.

- Various installation possibilities, special sizes and types (available on request

- Complete stainless steel construction.

- Installation brackets on the body (without support).

- High pressure condenser.

- Boiler blowdown heat recovery systems.

- RVST/S - carbon steel.

- RVST/SS - stainless steel

- RVST08, RVST12, RVST16, RVST18.

- EN 1092-1 PN 16 flanges.

- Special flanges on request.

- Vertical installation.

- Condensate inlet and outlet horizontal.

- See AD (assembly drawing).

Direct Steam Injection Humidifiers

Direct Steam Humidifers DSH

The flash tank is the main component of any flash or revaporized steam recovery system.

It can be used in all steam plants where high pressure condensate is reduced to a lower pressure generating revaporized steam; this steam can be used in low pressure process equipment or for energy saving.

Connections are flanged or special executions on request.

- Various installation possibilities, special sizes and types (available on request

- Complete stainless steel construction.

- Installation brackets on the body (without support).

- High pressure condenser.

- Boiler blowdown heat recovery systems

- RVST/S - carbon steel.

- RVST/SS - stainless steel.

- RVST08, RVST12, RVST16, RVST18.

- EN 1092-1 PN 16 flanges.

- Special flanges on request.

- Vertical installation.

- Condensate inlet and outlet horizontal.

- See AD (assembly drawing).

Packaged Water Heating Units amd Customised Equipment

Electric Condensate Recovery Unit ECRU

The ADCAMAT ECRU series electric condensate recovery unit is especially recommended for the transfer and lifting of high temperature water such as condensate, they are recommended for the transfer of high temperature water such as hot condensate. Standard models are prepared for flow rates up to 20 m3/h and higher on request.

The units consist of a condensate receiver (receiver), a metal support frame, electric pumps, level controls, valves, pre-wired control panel and piping for connections between the different elements of the units.

- Condensate tank - Completely made of AISI 316 stainless steel or carbon steel, with inlet connections, overflow, air vents, drain, pump feed outlets and a magnetic level indicator with bistable switches.

- Piping, valves and fittings - Includes full bore ball valves on pump suction inlets, manual regulating valves for manual adjustment of system head at pump discharge, piping, filters and pressure gauges.

- Metal frame - Made of structural steel (sandblasted and painted) or stainless steel (sandblasted).

- Pumps - Manufactured from cast iron or stainless steel, capable of handling hot condensate up to 98°C and designed for low NPSH.

- Control panel - Metal enclosure rated IP 65 or higher. Features alternating and cascade (simultaneity) functions, pump failure indication for each pump, high and low level alarms, pump dry run inhibitor, operating mode selector and voltage free telemetry terminals for remote statistics. The unit requires a three-phase 380 to 415 VAC, 50 Hz power supply.

- Thermally insulated vessel.

- Full or partial stainless steel construction.

- Alternative designs, including ATEX compliant versions.

- EC225 2T10 - 225 liter tank capacity, 2 m³/h flow rate and 10 m delivery head.

- EC225 4T10 - 225 liter tank capacity, 4 m³/h flow rate and 10 m discharge head.

- EC600 10T10 - Tank capacity of 600L, flow rate of 10 m³/h and discharge head of 10 m.

- EC600 10T20 - Tank capacity of 600L, flow rate of 10 m³/h and discharge height of 20 m.

- EC600 10T30 - Tank capacity of 600L, flow rate of 10 m³/h and discharge height of 30 m.

- EC600 20T10 - 600L tank capacity, 20 m³/h flow rate and 10 m discharge height.

- EC850 30T10 - 850L tank capacity, 30 m³/h flow rate and 10 m discharge height.

- EC850 30T20 - 850L tank capacity, 30 m³/h flow rate and 20 m discharge height.

- Others on request.

- Condensate is fed into the receiver through inlet connections, with stainless steel tubing, located at the top of the receiver. As condensate is pumped in, the level control system will initiate the pumping process. Under normal operating conditions, the pumps operate in alternating mode, which means that they alternate work at the end of each cycle. In case of peak loads, the level will continue to rise and the cascade switch will be activated, which will cause both pumps to run simultaneously to relieve this peak demand.

Electric Condensate Recovery Unit ECRUV

ADCAMat ECRUV series electric condensate recovery units are recommended in the transfer of high temperature water, such as hot condensate, to a higher elevation or pressure. This condensate is often used as boiler feedwater. Standard models are rated for flow rates up to 4 m³/h.

The units consist of a vertical condensate receiver (receiver), a metal support frame, electric pump, level controls, valves, pre-wired control panel and piping for connections between the various elements of the units

- Condensate vessel – Completely manufactured from carbon steel or AISI 316 stainless steel, with inlet connections, overflow, air vents, drain, pump feeding outlets and a set of conductive level switches.

- Metal frame – Manufactured from structural steel (sandblasted and painted) or stainless steel (sandblasted).

- Pump – Manufactured from stainless steel, capable of handling hot condensate up to 98 ºC and designed for low NPSH.

- Control panel – Metal enclose ure rated to IP 65 or higher. Features pump fault indication, level alarms, operating mode selector switch and volt-free telemetry terminals for remote stats. The unit requires a 3 phase, 380-415 V AC, 50 Hz power supply

- Thermal insulated vessel.

- Full or partial stainless steel construction.

- Different pumping capacities.

- Alternative designs.

- ECV150 2T10 - 150L tank capacity, 2 m³/h flow rate and 10 m delivery head.

- ECV225 4T10 - Tank capacity 225L, flow rate 4 m³/h and 10 m discharge head.

Others upon request.

- The condensate is brought into the vessel through the inlet connections, with stainless steel sparge pipes, located on the top of the vessel. As the condensate level rises it will trigger the level control system to start the pumping process.

Packaged Water Heating Unit PWHU

The ADCATherm PWHU packaged water heating units are designed

for instant hot water heating in a safe and efficient way, using steam

as primary fluid.

Each system is built to meet application and space requirements in a

compact skid package, ready for connection into the system, reducing

on-site labour and disruption time.

- Accurate water heating with simple and intuitive controls.

- Fully assembled and tested, saving design, assembly and commisioning time.

- Compactly mounted in a structural steel metal frame to save floor space.

- Tailor made to meet application and space requirements.

- Hot water side manufactured in austenitic stainless steel with automatic air venting.

- Fitted with ADCATherm PAT plate heat exchanger or ST shell & tube heat exchanger.

- Frame and/or primary side manufactured in stainless steel.

- Humidity separator set.

- Independent high limit set.

- Steam pressure reducing set.

- Pump trap set.

- Recirculation pump and bypass set.

- Primary and/or secondary side shut-off set.

- Buffer vessel for semi-instantaneous systems (WAVE).

- ADCATherm shell & tube heat exchanger.

- Thermal insulation.

- Wheels.

- Instant water heating for process and other applications.

- Flanged EN 1092-1 PN 16 or ASME B16.5 Class 150.

- Others on request

Flash Steam Heat Recovery Unit FRECO

The Adcatherm Freco compact flash steam recovery unit is a skid-mounted unit to facilitate the recovery of the energy contained in flash steam and condensate.

The Freco skid is especially recommended for heating a continuous flow of fluid, such as make-up water for boiler feed.

Non-continuous flow applications may require additional recirculation, relief valves or other devices to prevent damage to the system due to overheating and subsequent overpressure.

It is known that condensate return and recovery is beneficial and ensures remarkable efficiency. However, the condensate, which is initially at high temperatures, ends up expanding and losing most of its energy through the formation of flash steam inside the condensate collection tank and boiler feed.

On the other hand, feed water temperatures above 90ºC to the boiler feed pumps, when coming from atmospheric tanks, will normally cause cavitation in the pumps with consequent damage.

The Freco system prevents this problem since it is installed downstream of the pumps, using the high pressures which can be found there, allowing the condensate heating above 100 ºC, without the existence of any boiling, and naturally eliminating the chances of cavitation.

- Different types of materials and designs available, according to the application

- Atmospherically vented units, to avoid extra back pressure in the condensate return system.

- Steam, water, hot condensate and other fluids compatible with the construction.

- FRECO

- Condensate flow rate and temperature.

- Make-up water flow rate and temperature.

- Operating pressures.

- Steam boiler(s) capacity and operating pressure.

Tanks and Vessels

Boiler Feed Tank BFT

The BFT boiler feed tank is one of the most important devices in a boiler house. Its main function is to store make-up water and condensate, ensuring a reserve of treated water to supply the steam boilers. The feed water has to be treated to prevent the formation of scale in the boiler; in addition oxygen must also be removed so that corrosion in the boiler itself and in the steam lines is avoided (this situation is normally handled by specialists).

The consumption of the chemicals used to remove oxygen can be drastically reduced by using one of the various ADCAtherm thermal degassing processes (ADG, TDG, FCD) for the removal of oxygen and other non-condensable gases (mainly carbon dioxide).

Even if you decide not to use one of the above mentioned systems, ADCATherm boiler feed tanks will always be optimized according to the existing needs, i.e. being able to include water preheating as well as other obvious features of a true steam expert.

- Sandblasted and metalized internally and externally (externally painted).

- Prevents energy wasting.

- Can be installed on new or existing systems.

- Vertical and special designs for different applications.

- Complete stainless steel construction.

- Complete system including all necessary components.

- Ventilation condenser for energy recovery.

- Steam boiler feed water.

- BFT - steam boiler feedwater stanSteam.

- BFT - standard horizontal design.

- BFT/ADG or TDG - vessel and corresponding

- BFTV - special vertical design.

- With EN 1092-1 or ASME flanges.

- ISO or NPT threaded connections.

- Different connections on request.

- Carbon steel with stainless components.

- See ADG/TDG catalogs for typical installations.

- Standard horizontal installation. Vertical on request.

- Final dimensions and connections as per drawing supplied after order confirmation.

- as per drawing supplied after order confirmation.

- Insulation (not included) recommended after Standard horizontal installation.

Direct Live Steam use

Direct Steam Injector SI20

ADCA's SI20 series steam injectors are condensing injectors. They ensure a low noise and vibration level in tanks for fast water heating by direct steam injection.

Female threaded connections

- Quiet operation.

- Corrosion resistant.

- No moving parts.

- Complete system including vacuum breaker and self-acting temperature regulator.

- Different capacities and designs available upon request.

- Direct steam injection heating.

- SI20-4, SI20-5,5 , SI20-7 and SI20-8,5.

- 3/4".

- Female thread ISO 7 Rp.

- Horizontal or vertical installation.

- See IMI - Installation and maintenance instructions.

Direct Steam Injector SI115

ADCA's SI115 series steam injectors are condensing injectors. They ensure low noise and vibration in tanks for rapid water heating by direct steam injection.

Steam enters through the inlet casing, passes along the center of the heater and mixes with the cold water which is drawn in through radial orifices.

Female threaded connections.

- Quiet operation.

- Corrosion resistant.

- No moving parts.

- Complete system including vacuum breaker and automatic temperature regulator.

- Different capacities and designs available upon request.

- Direct steam injection heating.

- SI115.

- 1/2"

- Female thread ISO 7 Rp.

- Horizontal installation.

- See IMI - Installation and maintenance instructions.

- AISI 316 / 1.4401.

Direct Steam Injector SI125/140

ADCA's SI125 and SI140 series steam injectors are condensing injectors. They ensure low noise and vibration in tanks for rapid water heating by direct steam injection.

Steam enters through the inlet casing, passes along the center of the heater and mixes with the cold water that is sucked in through radial orifices.

Female threaded connections.

- Quiet operation.

- Corrosion resistant.

- No moving parts.

- Complete system including vacuum breaker and self-acting temperature regulator.

- Different capacities and designs available upon request.

- Direct steam injection heating.

- SI125 and SI140.

- 1" y 11/2".

- Female thread ISO 7 Rp.

- Horizontal installation.

- See IMI - Installation instructions.

- CF8M / 1.4408.

Steam Water Mixer ADCAMIX MX20

The ADCAMix MX20 is a series of steam/water mixers designed to provide a cheap and instantaneous source of low pressure hot water, by using existing steam and cold water supplies.

The mixer incorporates a safety device, to ensure that live steam cannot be accidentally ejected even if, for some reason, the cold water supply fails.

The water temperature at the outlet of the ADCAMix is easily controlled by using water and steam valves fitted at the inlets.

- Instant source of low pressure hot water.

- Safety device against accidental steam ejection.

- Non return valves included.

- Complete stainless steel construction.

- Quiet operation.

- Alternative steam valve if live steam spraying is required, e.g. for sterilisation.

- Stainless steel pedestal.

- Adjustable spray gun.

- Steam/water inlet valves.

- Hot water/steam hose.

- Stainless steel suspension for hose.

- Saturated steam and cold water.

- MX20 – stainless steel.

- 3/4" x 3/4".

- Female threaded ISO 7 Rp.

- Vertical wall installation.

- See IMI – Installation and maintenance instructions.

Water-Saving guns ADCAMIX SG20

The SG20 water saving spray gun is specially recommended to be used together with the Adcamix steam/water mixing valve.

By using this gun, water and energy costs can be considerably reduced, also contributing to the protection of the environment by avoiding the use of chemicals in cleaning processes.

The valve is opened and closed by operating the lever that regulates the flow, from a mist to a concentrated jet.

The locking position facilitates continuous operation.

The valve is designed for industrial use and is extremely robust. The rubber coating protects it against shock, heat and cold and makes it resistant to acids.

- Different colors for an additional price.

- Hot and cold water.

- SG20 (+50ºC); SG20H (+95ºC).

- 1/2".

- MAX. OPERATING PRESSURE: 24 bar

Exhaust Heads EH

The ADCA EH series exhaust heads were designed to protect personnel from injury and exterior of buildings from harmful effects of steam ejection to atmosphere. The head is fitted at the end of a vertical exhaust pipe and effectively retains the moisture separated from the steam for draining.

- Stainless steel separating element.

- Quiet operation.

- Reduces discharge velocity.

- Corrosion protection (sand blasted, metalized and painted).

- Complete stainless steel construction.

- Open vertical steam vent pipes in blowdown vessels, boiler feedtanks, etc.

- EH/S – carbon steel body.

- EH/SH – thermal spraying zinc coating and black painted.

- EH/SS – stainless steel body.

- 1" to 10"; DN 25 to DN 250.

- Flanged EN 1092-1 PN 16.

- Flanged ASME B16.5 Class 150.

- Others on request.

- Vertical installation.

- The drain should be directed to a safe place.

- Not recommended to fit at the discharge outlet of safety relief valves.

- See IMI – Installation and maintenance instructions.

Lifting pots LIPO

The ADCA LIPO series of condensate lifting pots were designed for installation in steam and condensate systems. They are particularly used in condensate lines where condensate must be transported without causing water hammers and noise and lifted to elevated condensate mains.

- Inspection hole for size 4" and DN 100.

- Lifting condensate to condensate mains.

- LIPOS – carbon steel.

- LIPOSS – stainless steel

- 1/2" to 4"; DN 15 to DN 100

- Flanged EN 1092-1 PN 16 or PN 40.

- Flanged ASME B16.5 Class 150

- Horizontal installation. Horizontal inlet and vertical outlet.

- See IMI – Installation and maintenance instructions